Top 10 Best Construction Machines for Every Project?

In the world of construction, choosing the right tools is crucial. Construction machines play a vital role in ensuring efficiency and effectiveness in projects. From heavy-duty excavators to versatile loaders, each machine has its unique purpose. Identifying the best machinery for specific tasks can be challenging.

When evaluating construction machines, consider the nature of your project. A small renovation requires different machines than a large-scale operation. For instance, a mini excavator may work wonders in tight spaces. Conversely, a bulldozer is ideal for larger areas needing significant earth moving.

Not all machines are created equal. Some may excel in performance but lag in durability. This is where careful consideration is essential. It’s not just about immediate results. Think long-term and reflect on maintenance needs. Investing in quality construction machines can save time and money. Balancing efficiency with reliability is key for any construction endeavor.

Overview of Construction Machines Essential for Various Projects

Construction projects vary widely, demanding different machines for different tasks.

Excavators, for instance, excel at digging foundations.

They are robust and versatile, tackling a range of earth-moving tasks. However, they require

skilled operators. Mismanagement can lead to

project delays or accidents.

Another essential machine is the bulldozer. It's powerful for

clearing land and moving materials. The blade’s angle can be adjusted for various tasks.

Yet, these machines can be challenging to navigate in tight spaces. That often leads to

frustration and inefficiency.

Concrete mixers are integral for any construction site

dealing with foundations and structures. They ensure consistent mixing, crucial for quality

results. But, if not cleaned properly, they can cause major setbacks. Time spent on maintenance

is often overlooked, yet essential. Balancing efficiency and upkeep remains a challenge in many projects.

Factors to Consider When Choosing Construction Machinery

When selecting construction machinery, several factors come into play. The type of project is crucial. Different tasks require specific machinery. For instance, excavation requires earth movers, while concrete work needs mixers. Evaluate the project's scale. Larger sites may need heavy-duty equipment, while smaller jobs could benefit from compact tools.

Cost is another vital consideration. Budget constraints can limit options. It's essential to balance quality and affordability. Sometimes, renting machinery makes more sense than purchasing. Maintenance needs can't be overlooked either. Some machines require frequent servicing. This can add to overall costs. Understanding the total cost of ownership is important.

Lastly, operator skill level matters. Not all workers can operate every machine. Ensure your team is properly trained. Consider the learning curve for complex machinery. This can affect project efficiency. If operators lack experience, it might slow down progress. Choosing the right construction machines requires careful thought. Do the research to avoid costly mistakes.

Top 10 Construction Machines with Versatile Applications

When it comes to construction projects, having the right machines is crucial. Versatile equipment can tackle a wide range of tasks, making them invaluable. Excavators, for example, are not just for digging holes. With various attachments, they can break concrete, lift heavy materials, and even perform grading tasks.

Another essential machine is the backhoe loader. This dual-purpose machine excels at excavation and loading. It can navigate tight spaces, which is beneficial for urban projects. Operators often find them easier to handle than larger machines. Still, they require skill and practice to master fully.

Skid steer loaders are popular for their compact size and agility. They can maneuver through confined areas while providing ample power. Their versatility lies in interchangeable attachments. From forks to brooms, they can adapt to various jobs. Yet, operators must be cautious; improper use can lead to accidents or damage. Each machine has unique capabilities, and understanding them ensures better project outcomes.

Top 10 Best Construction Machines for Every Project

Comparative Analysis of Machine Performance and Efficiency

When it comes to construction projects, selecting the right machine is crucial. Not all machines perform equally. Some excel in speed, while others focus on precision. This disparity can impact project timelines significantly. For example, excavators are renowned for their digging capabilities. However, their mobility is limited. In contrast, skid steers offer versatility but may lack the same digging depth.

Efficiency in construction machines can be a double-edged sword. A compact track loader may handle smaller jobs efficiently, yet struggles with heavy loads. Fuel consumption is another factor to consider. Machines that require more fuel might deliver power but at a cost. Analyzing fuel efficiency can lead to long-term savings. On the other hand, operators may overlook maintenance needs. Neglect can lead to downtime and affect overall project efficiency. Understanding the balance between power and fuel efficiency is key to optimizing performance.

Furthermore, the operator's experience plays a vital role in machine performance. A skilled operator can maximize a machine’s potential. However, inexperienced users can hinder performance. Inefficient operation might lead to project delays and increased costs. Ultimately, each choice in machinery should be reflected upon, ensuring it aligns with both the project requirements and operational capabilities.

Maintenance Tips for Optimal Performance of Construction Equipment

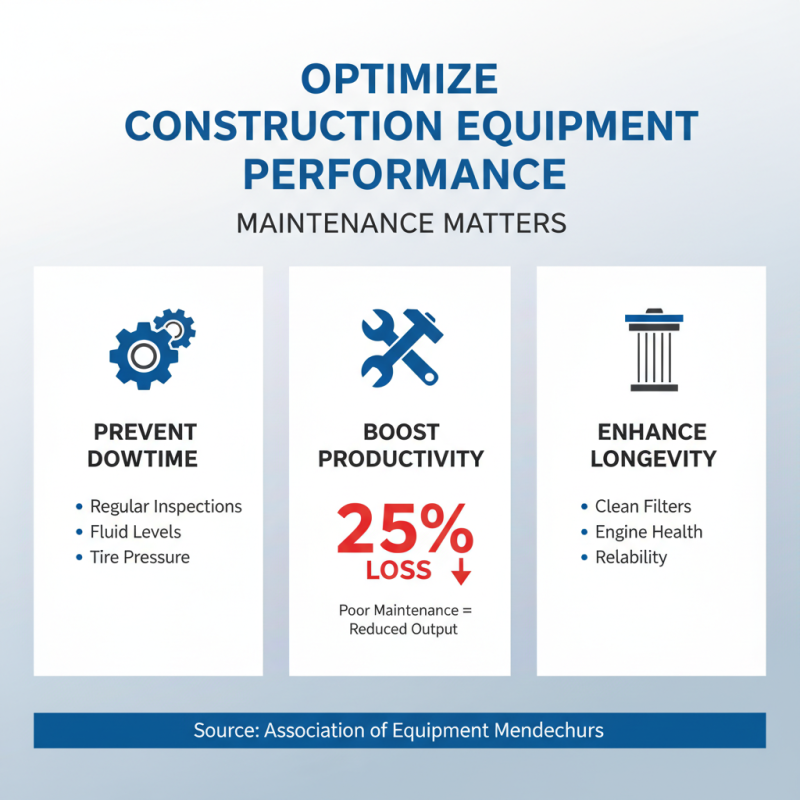

Proper maintenance of construction machines is crucial for optimal performance. Regular inspections can prevent unexpected downtime. According to a report from the Association of Equipment Manufacturers, poorly maintained machines can lose up to 25% of their productivity. Simple checks like fluid levels, tire pressure, and filters can significantly impact performance.

In addition, daily maintenance routines should not be overlooked. Many operators skip these vital tasks due to time constraints. However, failure to conduct these checks may lead to costly repairs. Equipment lifespan can diminish by 30% without proper upkeep. Many professionals argue that investing time in maintenance pays off in the long run.

Training operators is also essential. Understanding basic maintenance can enhance safety and efficiency. Reports indicate that 70% of equipment failures are linked to operator errors. Regular training sessions can mitigate these risks. Creating a culture of responsibility around maintenance is key for any project’s success.

Related Posts

-

Top 5 Must Have Construction Machines for Every Builder

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

2026 How to Choose the Right Earth Moving Equipment?

-

2026 Top Construction Equipment Innovations You Need to Know?