10 Best Machine Tools for Precision Engineering?

In the realm of precision engineering, the right machine tools are invaluable. These tools shape, cut, and manipulate materials into intricate designs. They significantly impact the quality and accuracy of engineered products.

Choosing the best machine tools requires thoughtful consideration. Each tool's unique features can enhance precision or fail to meet expectations. For instance, CNC machines provide automation and consistency, but they may demand a steep learning curve.

Moreover, the market is flooded with options. Some tools excel in versatility, while others focus on specialty tasks. It’s essential to evaluate what fits your specific needs. Reflecting on your choices can lead to better outcomes and improved efficiency. This exploration into the ten best machine tools will guide you in making informed decisions for your engineering projects.

Overview of Precision Engineering and Its Importance

Precision engineering plays a critical role in various industries, including aerospace, automotive, and medical sectors. This discipline focuses on creating components with extremely tight tolerances. According to industry reports, the global precision engineering market is expected to reach $25 billion by 2027, growing annually at about 8%. This growth highlights the increasing need for high-quality, precise components in modern manufacturing.

In precision engineering, even the smallest deviations can lead to significant failures. For instance, a miscalculation of just 0.01 mm can affect a component's performance. Companies must invest in advanced machine tools to achieve these tight tolerances. However, not all tools guarantee the desired precision. Reports indicate that around 30% of machine failures stem from improper calibration or worn-out components. This reality shows that precision engineering still faces challenges.

Current trends emphasize automation and smart technology in enhancing precision. While automation reduces human error, it also introduces a new set of complexities. Data shows that 40% of engineers believe that reliance on technology can lead to skill degradation. Striking the right balance between technology and skilled craftsmanship remains essential. This dual focus on high-tech tools and human expertise is vital for the continued advancement of precision engineering.

10 Best Machine Tools for Precision Engineering

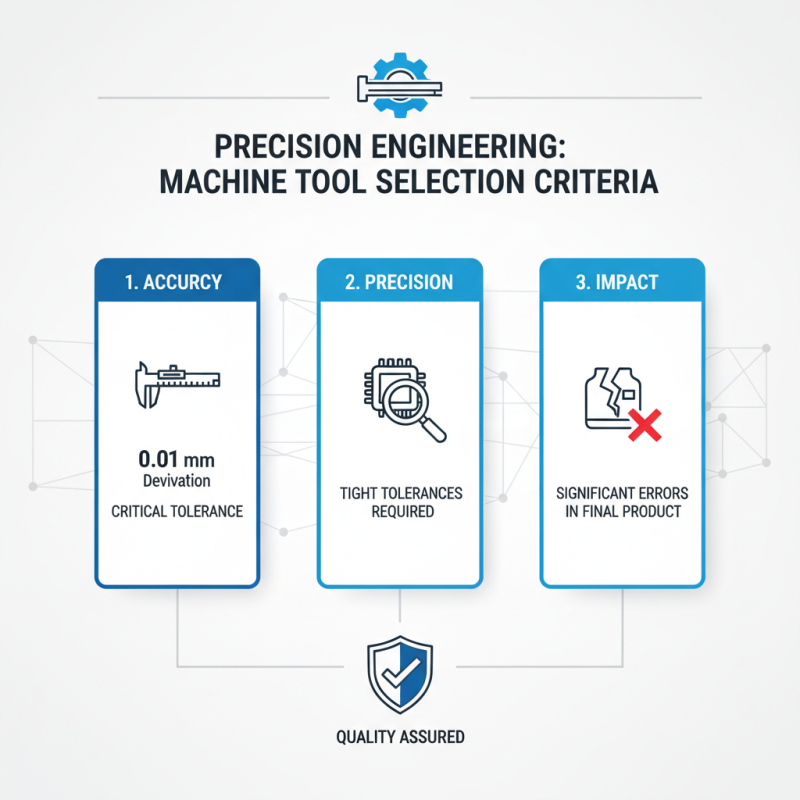

Criteria for Selecting the Best Machine Tools

When selecting the best machine tools for precision engineering, several criteria come into play. Accuracy is paramount. According to a recent industry report, a mere 0.01 mm deviation can lead to significant errors in the final product. Hence, precision machining tools must maintain tight tolerances.

Durability is another critical factor. Machine tools must withstand heavy use and high-stress conditions. A tool’s lifespan can be shortened by inadequate maintenance. Regular inspections and proper lubrication are essential. Many facilities overlook this aspect, resulting in unexpected downtimes and costly repairs.

Additionally, versatility cannot be ignored. Tools that can perform multiple functions save both space and time. However, finding a balance between specialization and versatility can be challenging. It requires careful consideration of operational needs. Sometimes, a more specialized machine is better, despite its limited range. Evaluating the specific requirements is vital to avoid missteps in investment.

Top 10 Machine Tools for Precision Engineering

Precision engineering requires the right tools. Selecting the top machine tools ensures accuracy and efficiency in production. These tools affect the quality of work and the outcome of projects. Among the most crucial are CNC machines. They automate processes, reducing human error and enhancing precision.

Milling machines are also vital. Their ability to create complex shapes is unmatched. Additionally, lathes play a pivotal role in shaping materials. However, one might overlook maintenance. Neglecting regular checks can lead to significant issues. There's always room for improvement in operations. Too many forget the importance of operator training, which greatly impacts overall effectiveness.

Other tools like grinders and laser cutters bring unique advantages. They can achieve fine finishes and intricate designs. However, every tool has limitations. It’s essential to understand when one tool is better than another for a specific task. Reflection on past experiences can enhance future decisions, leading to better outcomes and greater precision.

Comparative Analysis of Featured Machine Tools

Precision engineering relies heavily on the quality and capability of machine tools. In a recent industry report, it was highlighted that up to 25% of machining errors arise from inadequate tooling. This emphasizes the need for superior machine tools that consistently deliver high precision. The analysis reveals that factors such as build quality, spindle speed, and control systems greatly influence performance and accuracy.

When evaluating machine tools, consider their adaptability. Some machines excel in complex geometries, while others shine in high-volume production. Industry data suggests that machines with a higher RPM are generally more versatile. However, they can also increase production costs and maintenance needs. It's essential to weigh these aspects before making a decision.

Tips: Always analyze your specific needs before investing. Understand workload, and future demands, and trial machine tools when possible. Regular maintenance can prevent significant issues down the line. Ultimately, continuing education about technological advancements can help in selecting tools that align with future trends in precision engineering.

10 Best Machine Tools for Precision Engineering

| Machine Tool | Type | Max Precision (µm) | Weight (kg) | Price Range (USD) |

|---|---|---|---|---|

| CNC Milling Machine | Milling | 5 | 1000 | 10,000 - 20,000 |

| Lathe Machine | Turning | 3 | 800 | 5,000 - 15,000 |

| EDM Machine | Electrical Discharge Machining | 2 | 1200 | 20,000 - 35,000 |

| Surface Grinder | Grinding | 1 | 900 | 8,000 - 18,000 |

| CNC Router | Routing | 10 | 700 | 5,000 - 25,000 |

| Laser Cutter | Cutting | 0.1 | 600 | 10,000 - 30,000 |

| Plasma Cutter | Cutting | 0.5 | 500 | 3,000 - 15,000 |

| CNC Plasma Table | Cutting | 0.2 | 1200 | 12,000 - 28,000 |

| 3D Printer | Additive Manufacturing | 50 | 200 | 2,000 - 10,000 |

| Vertical Bandsaw | Sawing | 0.5 | 300 | 1,500 - 5,000 |

Future Trends in Machine Tools for Precision Engineering

The future of machine tools in precision engineering is dynamic and transformative. Emerging technologies, such as AI and automation, are beginning to reshape this sector. Factories are adopting smart machines that can adapt on the fly. This means more precision and less human error. Additionally, augmented reality could revolutionize how operators interact with machines.

Sustainability is another significant trend. Manufacturers are exploring eco-friendly materials and energy-efficient machines. However, this transition is not without challenges. Finding the balance between cost and sustainability remains a complex question. As companies invest in greener technologies, they must consider initial expenses and long-term benefits.

Embracing data analytics is becoming crucial. Tools that collect and analyze performance data can improve productivity. Yet, many companies struggle to implement these systems effectively. There is often a gap between understanding the technology and actual application. Continuous learning and adaptation will be necessary for success in this evolving landscape.

Related Posts

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

Essential Tips for Choosing Industrial Machinery That Boost Efficiency and Productivity

-

Top 10 Industrial Machinery Trends Shaping the Future of Manufacturing

-

How to Choose the Right Industrial Machinery for Your Business Needs in 2025

-

10 Essential Tips for Choosing Machinery and Equipment in Your Business?