How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

In the rapidly evolving landscape of construction in 2025, the selection of the right heavy machinery stands as a critical factor influencing project efficiency and success. With advancements in technology, safety standards, and environmental regulations, constructors are faced with an array of sophisticated machinery options that cater to diverse tasks and operational needs. Understanding how to choose the right heavy machinery is paramount for optimizing performance, reducing downtime, and ensuring safety on-site.

As construction projects become more complex, the implications of improper machinery selection can lead to increased costs and project delays. Factors such as the size of the project, ground conditions, and specific project requirements must be carefully assessed to determine the most suitable equipment. The integration of smart technologies and automation in heavy machinery also plays a significant role in enhancing productivity and sustainability, making it essential for construction professionals to stay abreast of these developments.

In this guide, we will explore the key considerations for selecting heavy machinery tailored to your construction projects in 2025. By examining various aspects such as machinery capabilities, operational efficiency, and environmental impact, this discussion aims to equip industry professionals with the insights needed to make informed decisions that will drive their projects to success.

Understanding Different Types of Heavy Machinery for Construction

When embarking on a construction project, understanding the different types of heavy machinery available is crucial for ensuring efficiency and effectiveness on the job site. Heavy machinery can be broadly categorized into several main types, each serving specific functions. Excavators are essential for digging and earthmoving tasks, typically featuring a rotational cab and an extendable arm that allows for precise digging in various terrains. These machines are indispensable for foundation work, trenching, and large-scale site preparation.

Another vital category includes bulldozers, known for their powerful blades that can push large quantities of materials across the site. They are primarily used for grading land and moving debris, making them ideal for clearing sites and leveling ground before construction begins. Additionally, cranes play a pivotal role in lifting heavy materials to high elevations, facilitating the construction of multi-story buildings. Understanding the specific capabilities and functions of these machines allows construction managers to select the right equipment based on the project requirements, thus optimizing resources and enhancing productivity on site.

Assessing Project Requirements and Objectives for Machinery Selection

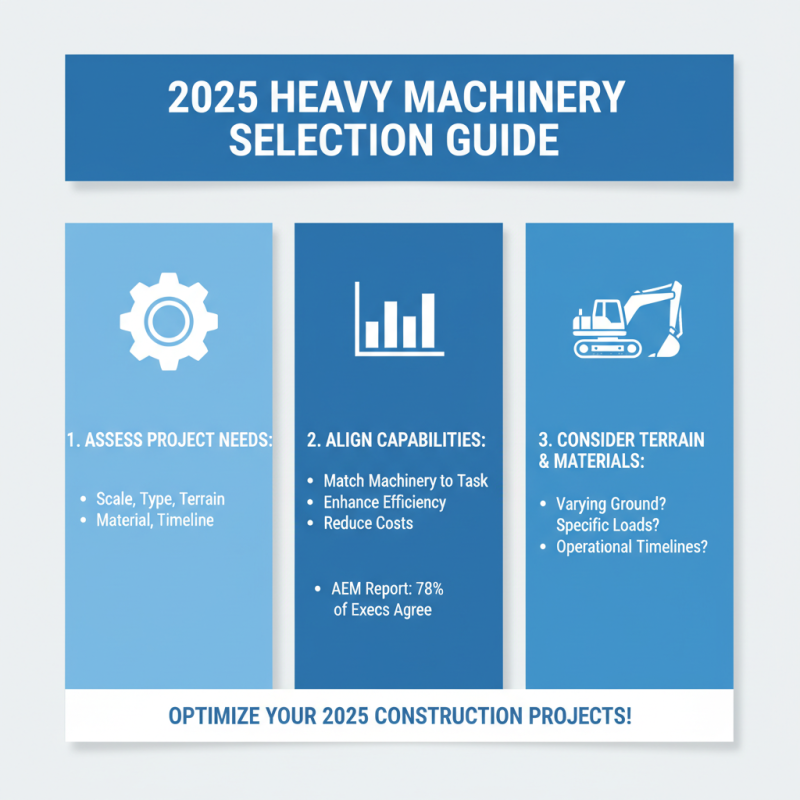

When embarking on a construction project in 2025, selecting the appropriate heavy machinery is crucial to meet both project requirements and objectives. The initial step in this process involves a comprehensive assessment of the project scale, type, and intricacies. According to a recent industry report by the Association of Equipment Manufacturers (AEM), 78% of construction executives emphasize the importance of aligning machinery capabilities with project demands to enhance efficiency and reduce overhead costs. This alignment is particularly vital in projects that entail varying terrains, material types, or specific operational timelines.

In addition to understanding project specifics, analyzing the objectives of machinery selection plays a pivotal role. Whether the goal is to minimize operational costs, increase productivity, or ensure sustainability, these objectives should inform decisions. A study by the Construction Industry Institute revealed that projects utilizing the right machinery saw a productivity increase of up to 25%, driving the cost-effectiveness of the entire undertaking. By carefully evaluating the requirements and objectives, construction managers can adopt a strategic approach to machinery selection that not only meets immediate needs but also positions the project for long-term success.

Evaluating Features and Technologies in Heavy Machinery

When selecting heavy machinery for construction projects in 2025, evaluating the features and technologies of available options is paramount. Modern heavy machinery is increasingly integrated with advanced technologies such as automation, telematics, and machine learning. These features not only enhance operational efficiency but also improve safety on job sites. For instance, autonomous machines can execute repetitive tasks with precision, allowing skilled operators to focus on more complex challenges. It's essential to assess how these innovations align with your project requirements, as choosing equipment with outdated technology may hinder productivity.

Moreover, the versatility and scalability of heavy machinery are crucial considerations. Equipment designed for multi-functionality can reduce the need for multiple machines, streamlining operations and ultimately saving costs. Features such as modular attachments or adaptable settings enable a single piece of machinery to accomplish various tasks. Additionally, evaluating the ease of maintenance and access to support services is vital when choosing machinery, as this can significantly impact long-term operational costs and project timelines. By carefully considering these features and advancements, construction managers can select the right heavy machinery that meets the demands of their projects while ensuring efficiency and safety.

Budget Considerations and Financing Options for Heavy Machinery

When selecting heavy machinery for construction projects in 2025, careful consideration of budget constraints and financing options is paramount. According to a report by the Global Construction Outlook, the heavy machinery market is projected to grow to $250 billion by 2025, driven by increased infrastructure investments. However, acquiring the right machinery comes with significant costs; thus, construction firms must assess their financial capabilities before making a decision. A detailed budget should include not only the purchase or lease price but also operational costs such as maintenance, fuel, and insurance, which can account for over 30% of a machine’s lifecycle costs.

Financing options play a critical role in effectively managing these expenses. Many contractors are opting for leasing machinery instead of outright purchases, which can alleviate upfront financial burdens. The Machinery Leasing Association reports that leasing can save companies approximately 15-20% compared to purchasing, especially for high-demand machines that may not be needed year-round. Additionally, some financial institutions offer specialized construction equipment loans with competitive interest rates. By exploring these options, construction companies can better align their heavy machinery acquisitions with their overall financial strategy, allowing them to stay within budget while ensuring they are well-equipped to handle ongoing and future projects.

Heavy Machinery Cost Comparison for Construction Projects in 2025

This bar chart illustrates the average costs of different types of heavy machinery required for construction projects in 2025. It is essential to consider these costs when budgeting and financing your projects.

Maintenance and Support Services for Long-Term Machinery Efficiency

In 2025, selecting the appropriate heavy machinery for construction projects will hinge not just on immediate performance but also on the long-term efficiency facilitated by robust maintenance and support services. According to a report by the Construction Industry Institute, effective maintenance protocols can reduce equipment downtime by up to 25%, significantly influencing project timelines and budget adherence. Therefore, construction companies must prioritize machinery that comes with comprehensive post-purchase support, including regular maintenance schedules and technician availability to ensure optimal operation throughout the equipment's lifecycle.

Moreover, a study conducted by the Association of Equipment Manufacturers highlights that 60% of heavy machinery failures can be traced back to inadequate maintenance practices. This reality underscores the importance of investing in machinery with strong warranty programs and proactive service agreements. As the industry moves toward greater automation and smart technologies, having access to advanced diagnostic tools can further enhance equipment resilience. In light of these findings, construction firms are encouraged to forge partnerships with service providers that offer extensive maintenance services and technical support, ensuring their machinery remains efficient and reliable for years to come.

Related Posts

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project

-

Top 10 Essential Tips for Choosing Euro Machinery in Your Industry

-

How to Find the Best Deals at Machine Tool Auctions with Industry Insights

-

Why Choose an Equipment Trader: Benefits for Buyers and Sellers in Construction

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

Top 5 Second Hand Industrial Equipment Options for Your Business Needs