How to Choose the Right Metal Working Machines for Your Projects

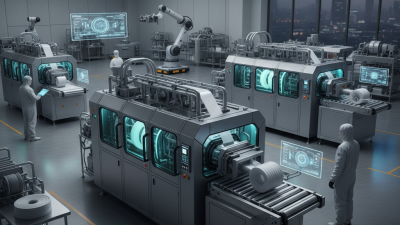

In the ever-evolving landscape of manufacturing, selecting the right metal working machines is a critical factor that can significantly influence the success of any project. According to a recent report by the International Federation of Robotics, the global market for metal working machinery is projected to reach $100 billion by 2025, highlighting the increasing reliance on advanced technologies in this sector. The precise selection of equipment not only enhances productivity but also optimizes efficiency, thereby reducing operational costs.

Metal working machines come in various types, each tailored to specific tasks—be it cutting, shaping, or assembling metal components. Industry expert Dr. Emily Hart, a noted authority in manufacturing technologies, emphasizes the importance of this decision: "Choosing the right metal working machines is essential for achieving the desired precision and the overall quality of the end product." This underscores that the right equipment is a crucial investment that can help businesses meet stringent production demands while adhering to quality standards. As companies navigate the complexities of their projects, understanding the functionalities and capabilities of different metal working machines is paramount to making an informed decision that aligns with their operational goals.

Factors to Consider When Selecting Metal Working Machines for Projects

When selecting metalworking machines for your projects, several critical factors must be considered to ensure you choose the right equipment. Firstly, assess the specific requirements of your project, including the types of materials you’ll be working with, their hardness, and the complexity of the designs. A survey by the National Association of Manufacturers indicates that over 75% of manufacturers report productivity improvements when using the right machines tailored to their specific tasks. Therefore, thorough pre-planning can often lead to better quality output and more efficient processes.

Another important factor is the machine's capabilities, including its precision, speed, and versatility. The demand for precision machinery is increasing, with a report from Technavio forecasting a compound annual growth rate (CAGR) of 5.3% in the CNC machine market through 2025. This growth is driven by industries such as aerospace and automotive, where precision is critical. Therefore, identifying the necessary specifications before making a purchase or lease can significantly enhance productivity and reduce rework.

Tips: When evaluating metalworking machines, consider starting with a basic requirement checklist that includes factors such as the maximum material thickness, the material types, and specific tolerances. Additionally, prioritize machines that offer ease of maintenance and support, as this can greatly reduce long-term operational costs. Lastly, consult with industry professionals or review case studies related to similar projects to gain insights into which machines may yield the best results for your specific applications.

Understanding Different Types of Metal Working Machines and Their Uses

When it comes to metalworking projects, selecting the appropriate machines is crucial for both efficiency and precision. Various types of metalworking machines serve different purposes, and understanding these can significantly impact the outcome of your work. For instance, lathes and milling machines are essential for shaping materials. Lathes rotate the metal workpiece against a cutting tool, allowing for efficient shaping of cylindrical parts, while milling machines use rotating cutting tools to remove material from a workpiece, providing versatility in complex shapes and features.

Another significant category includes welding machines, which are vital for joining metal parts together. Different welding techniques, such as MIG, TIG, and stick welding, utilize different machines tailored to specific applications. For instance, MIG welding is popular for its ease of use and speed, making it ideal for projects requiring rapid assembly. On the other hand, plasma cutters are excellent for cutting through thick metal plates, offering clean and precise cuts. Understanding these distinctions not only helps in choosing the right machine but also enhances the overall quality of your metalworking projects.

Metal Working Machines Usage Comparison

This chart displays the frequency of usage for different types of metal working machines commonly used in workshops. The data indicates that welding machines are the most frequently used, followed by milling machines, while press brakes are used the least.

Key Specifications and Features to Look for in Metal Working Machinery

When selecting metalworking machines for your projects, it's essential to focus on key specifications and features that cater to your specific needs. First and foremost, consider the machine's capacity and size. The working area should accommodate the dimensions of the materials you plan to use, ensuring efficient and accurate processing. Additionally, the machine's power and speed specifications are crucial; a higher power output can facilitate cutting through tougher materials, while adjustable speed settings allow for versatility with various types of metalwork.

Another important feature to assess is the machine's ease of use and safety measures. Look for intuitive controls and user-friendly interfaces that can enhance productivity and minimize the learning curve. Safety features such as emergency stop buttons, protective enclosures, and safety interlocks are paramount to safeguard operators during use.

Furthermore, consider the machine's compatibility with various accessories and tools, which can significantly expand its functionality and adaptability for different projects. Ultimately, investing time in evaluating these specifications will ensure that you choose a metalworking machine that aligns with your project requirements.

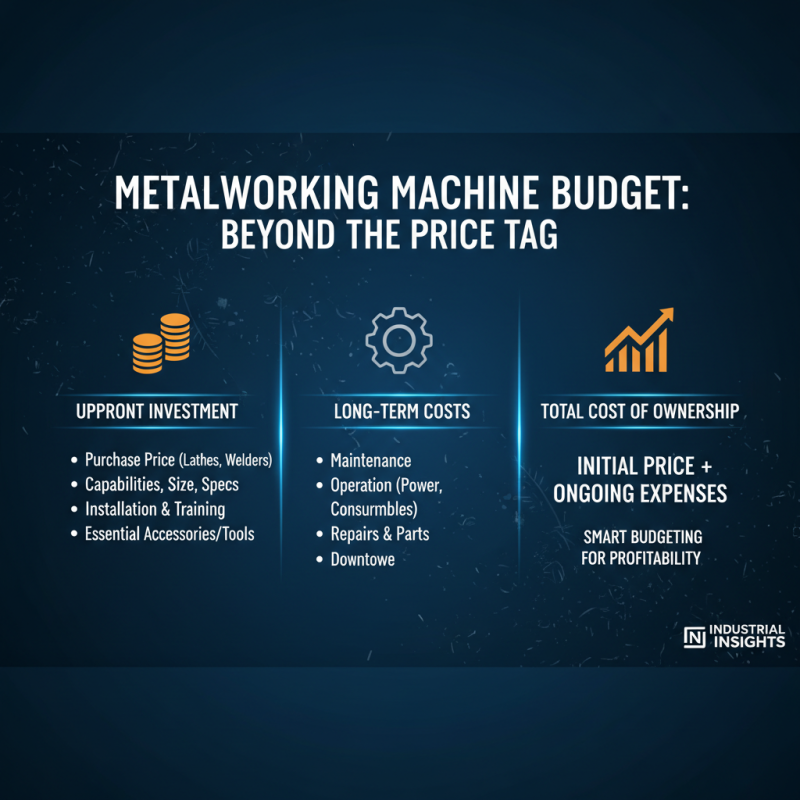

Cost Analysis: Budgeting for Metal Working Machines and Maintenance

When budgeting for metal working machines, it is essential to consider not only the initial purchase price but also the long-term costs associated with maintenance and operation. The upfront investment for machines such as lathes, mills, or welders can vary significantly depending on their capabilities, size, and specifications. In addition to the purchase price, buyers should factor in costs related to installation, training, and necessary accessories or tools that may be required to ensure the machines function optimally.

Maintenance costs are another critical aspect to include in your financial planning. Regular upkeep can prevent costly breakdowns and prolong the lifespan of your machinery. It is advisable to allocate a portion of your budget for routine checks, repairs, and the replacement of consumables, which are essential for maintaining efficiency. Furthermore, consider potential operational costs such as electricity, consumables, and labor, as these can accumulate over time, impacting your overall budget. By performing a thorough cost analysis, you can make informed decisions that align with your financial capabilities while ensuring that you invest in machines suited for your metalworking needs.

Safety Standards and Compliance in the Metal Working Industry

In the metalworking industry, adherence to safety standards and compliance regulations is paramount to protect workers and ensure operational efficiency. According to the Occupational Safety and Health Administration (OSHA), approximately 5,333 workplace fatalities were recorded in the United States in a recent year, underscoring the critical need for stringent safety measures in environments where metalworking machines are operated. Industry reports indicate that metal fabrication facilities that prioritize safety and compliance not only enhance employee well-being but also improve productivity by minimizing downtime due to accidents or health-related issues.

Compliance with safety standards such as those set forth by the American National Standards Institute (ANSI) and the National Institute for Occupational Safety and Health (NIOSH) is essential for minimizing risks associated with metalworking operations. For example, proper machine guarding, adequate ventilation, and effective training programs can significantly reduce incidents of workplace injuries. A study by the Fabricators & Manufacturers Association (FMA) showed that facilities implementing comprehensive safety training programs can experience a 20-30% reduction in injury rates. This data accentuates the importance of investing in not only the right machinery but also in robust safety protocols, thereby fostering a safer work environment and contributing to the overall success of metalworking projects.

How to Choose the Right Metal Working Machines for Your Projects - Safety Standards and Compliance in the Metal Working Industry

| Machine Type | Key Features | Safety Standards | Compliance Requirements |

|---|---|---|---|

| CNC Milling Machine | Precision cutting, Automatic tool changing | ANSI B11.6 | OSHA standards for machine safeguarding |

| Laser Cutting Machine | High-speed cutting, Minimal heat affect zone | IEC 60825-1 | Laser safety compliance, CE mark |

| Welding Machine | Arc welding, High duty cycle | AWS and ANSI Z49.1 | Electrical safety codes |

| Bending Machine | Hydraulic or mechanical bending, CNC control | ISO 12100 | Protection against moving parts |

| Surface Grinder | Precision surface finishing, Manual or automatic | ANSI B11.10 | Lockout/tagout procedures |

Related Posts

-

2025 Guide: How to Choose the Best Extruder Machine for Your Needs

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

What is Machinery Parts and Their Importance in Modern Manufacturing

-

Why Choose an Equipment Trader: Benefits for Buyers and Sellers in Construction

-

How to Find the Best Deals at Machine Tool Auctions with Industry Insights