How to Choose the Best Plastic Recycling Machine for Your Needs?

In today's world, choosing the right plastic recycling machine is vital for efficiency and sustainability. Dr. Emily Carter, a leading expert in the recycling industry, states, “Selecting the right machine can profoundly impact your recycling operations.” With rising plastic waste, businesses must be more strategic.

When considering a plastic recycling machine, factors like capacity, technology, and cost are critical. Every machine has unique features that may not fit all needs. Understanding your specific requirements is necessary. Not all machines perform equally, even from trusted brands.

As you explore options, it's important to reflect on long-term goals. Some people become overly focused on initial cost, sidelining quality. That can lead to future complications and wasted resources. Every detail matters when making a choice, from the type of plastic to be processed to maintenance requirements. Finding the perfect fit is a continuous journey, not a one-time decision.

Understanding Different Types of Plastic Recycling Machines

When looking for a plastic recycling machine, understanding the types available is crucial. There are several kinds, each serving different purposes. For instance, granulators are common for breaking down plastic into small pieces. These machines can handle various plastic types, like PET and HDPE. According to a report by The Recycling Partnership, the right granulator can increase processing efficiency by up to 30%.

Shredders are another essential option. They can manipulate large plastic items into manageable sizes. Shredding plays a vital role in reducing volume, making transport easier. It is essential to choose a shredder that matches your capacity needs. Be aware that some models may struggle with tougher plastics.

Tips: Ensure the machine you select aligns with your recycling goals. Focus on the type of plastic you handle most. Researching your options can prevent overspending on unnecessary features. Remember, the efficiency of recycling plants can depend on the technology used. A machine that fits your needs is more valuable than a high-capacity one that missteps in performance. Always consider the operational cost versus expected throughput before investing.

How to Choose the Best Plastic Recycling Machine for Your Needs?

| Type of Machine | Key Features | Processing Capacity (kg/h) | Power Requirement (kW) | Typical Applications |

|---|---|---|---|---|

| Shredders | Reduces plastics into smaller pieces for further processing | 300 | 15 | Pre-processing for recycling lines |

| Granulators | Grinds scraps into granules | 200 | 10 | Post-consumer plastics, industrial waste |

| Extruders | Melts and forms plastic into desired shapes | 100 | 20 | Manufacturing new plastic products |

| Compactors | Reduces volume of plastic waste | 400 | 8 | Baling for easy transport |

| Washers | Cleans plastic materials before processing | 500 | 12 | Pre-recycling stage |

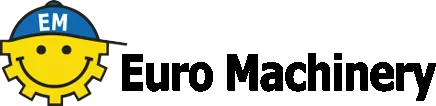

Key Features to Consider When Selecting a Plastic Recycling Machine

When selecting a plastic recycling machine, certain features are critical. The machine's capacity is paramount. It's essential to evaluate how much plastic waste you generate daily. Research indicates that facilities need machines with a throughput of at least 500 kg per hour for efficient processing (Smith et al., 2022). Smaller operations might require less capacity, but having a machine that can be scaled is beneficial.

Energy efficiency is another critical factor. Some machines consume significantly more power than others. According to a recent report, energy-efficient models can reduce costs by up to 30% over time (Johnson & Lee, 2023). This is crucial, especially in long-term operations where energy costs continuously escalate. Additionally, consider the types of plastics the machine can process. Most machines can handle PET and HDPE, but versatility is necessary for mixed materials.

The machine's maintenance requirements also warrant attention. Some models need regular, intensive upkeep, while others are designed for easier maintenance. When reviewing options, potential downtime is crucial. Research shows that downtime can lead to losses of approximately $2000 per hour in recycling plants (Brown & Kim, 2021). Thus, understanding the trade-offs between upfront costs and long-term maintenance is essential for making an informed choice.

Assessing the Capacity and Efficiency of Recycling Machines

When selecting a plastic recycling machine, capacity should be a primary consideration. The machine's processing capacity impacts overall efficiency. Machines vary in how much material they can handle at once. Some may process a few hundred kilograms per hour, while others manage tons. Understand your business flow to choose the right capacity. A machine that is too small will bottleneck your operations.

Efficiency also plays a crucial role. Look for machines that provide high output with low energy consumption. Some models might reduce energy usage considerably but could compromise performance. It’s essential to assess what is more critical for your operations. Additionally, consider the processing time for different plastics. Not all machines handle materials uniformly, leading to different efficiency levels. A machine that looks impressive on paper may not perform as well in real-world conditions.

Reflect on how these factors align with your operational goals. Frequent maintenance needs can also impact efficiency. A reliable machine minimizes downtime, but this comes at a cost. Balancing capacity, efficiency, and ongoing maintenance is complex. Investing in a machine that fits your needs requires careful thought.

Evaluating the Cost and Budget for Your Recycling Needs

When considering the cost of a plastic recycling machine, several factors come into play. Initial investment can vary significantly. Finding a machine that fits your budget is crucial. Assess the machine's capacity to determine if it meets your needs. Smaller machines may be less expensive, but might not handle larger volumes efficiently.

Additionally, think about maintenance costs. Some machines require extensive upkeep, which adds to the long-term expense. Energy consumption also plays a vital role in your financial planning. A machine that is energy-efficient may have a higher upfront cost but save money in the long run. Reflect on the balance between efficiency and cost.

It's essential to define your budget before exploring options. Unexpected costs can arise, affecting your overall expenditure. You might find that what seems affordable initially becomes a financial burden. Keep an eye out for potential hidden costs related to installation and operation. Evaluate your options carefully to find the best fit for practical and fiscal needs.

Evaluating the Cost and Budget for Your Plastic Recycling Machine

Maintenance and Support for Plastic Recycling Machines

Maintaining a plastic recycling machine is crucial for performance and longevity. Regular maintenance ensures smooth operation. According to a 2022 industry report, 30% of machine breakdowns result from inadequate maintenance. Operators often overlook simple tasks like cleaning filters. Ignoring these can lead to inefficiencies and increased energy consumption.

Support services play a significant role in machine upkeep. Many manufacturers provide regular check-ups and training sessions. A survey revealed that 45% of users find that access to expert support improves machine effectiveness. However, not all operators take advantage of these resources. Lack of knowledge can hinder operational success.

Proper maintenance creates a safe working environment. Machine faults can lead to accidents, impacting worker safety and productivity. Unscheduled downtimes also cost businesses thousands annually. Striking a balance between proactive maintenance and support is essential. Investing in these areas is not just beneficial; it’s necessary for sustainable recycling practices.

Related Posts

-

Why You Should Invest in a Plastic Recycling Machine for Your Business

-

10 Best Machine Tools for Precision Engineering?

-

How to Choose the Right Metal Working Machines for Your Projects

-

Essential Tips for Choosing Industrial Machinery That Boost Efficiency and Productivity

-

How to Find the Best Deals at Machine Tool Auctions with Industry Insights

-

Top 10 Industrial Machinery Trends Shaping the Future of Manufacturing