Top 10 Essential Tips for Choosing Euro Machinery in Your Industry

In the competitive landscape of modern industry, selecting the right Euro machinery is paramount for enhancing productivity and maintaining operational efficiency. According to industry expert John Smith, a respected authority in the field of manufacturing technologies, "The right machinery not only increases output but can significantly reduce long-term operational costs." His insights reflect the critical role that machinery selection plays in achieving business success.

As industries evolve, the demand for high-quality, reliable Euro machinery has surged. With an abundance of options available, making an informed choice can be overwhelming. This guide, outlining the top ten essential tips for selecting Euro machinery, aims to simplify the decision-making process. By understanding key factors such as technological advancements, maintenance requirements, and compatibility with existing operations, businesses can better navigate the complexities of equipment selection.

Ultimately, investing in the appropriate Euro machinery is not merely a transaction; it is a strategic decision that can influence a company’s competitiveness and growth trajectory. With the right tools, organizations can not only meet current demands but also position themselves for future success in their respective industries.

Factors to Consider When Selecting Euro Machinery for Your Industry

When selecting Euro machinery for your industry, several key factors demand attention to ensure you make an informed decision. First and foremost, consider the machinery's compatibility with your specific production processes. Evaluate the required specifications, such as capacity, precision, and automation level, to ensure the selected machinery meets your operational needs. Conducting a thorough analysis of your workflow and identifying which machinery will enhance efficiency and productivity is crucial for a successful investment.

Another important factor is the machinery's energy efficiency and environmental impact. With increasing regulations and industry standards aimed at sustainability, it’s essential to choose machinery that not only reduces operational costs but also aligns with green initiatives. Examine energy consumption ratings and look for eco-friendly features that can minimize your carbon footprint and contribute positively to the environment. Finally, assess the availability of support and spare parts for the machinery, as access to reliable maintenance services can significantly impact the longevity and performance of your investment. Prioritizing these factors will help you select the right Euro machinery that aligns with your operational goals and industry standards.

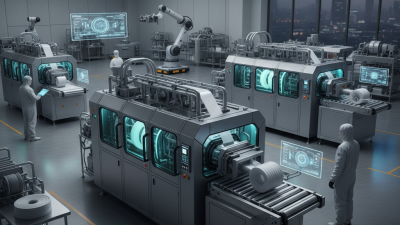

Understanding Your Industry's Specific Machinery Needs

When selecting machinery within various industries, it is crucial to have a clear understanding of your specific operational needs. For instance, the manufacturing sector has reported that nearly 40% of all machinery investments fail to deliver the expected return on investment due to a mismatch between machinery capabilities and production requirements (McKinsey & Company, 2022). Identifying your operational goals—whether it's increasing efficiency, enhancing product quality, or both—can guide you in choosing machines that align with these objectives. This tailored approach ensures that the machinery not only meets current demands but is also adaptable to future changes in production needs.

Furthermore, consulting industry-specific benchmarks can yield significant insights into machinery characteristics that matter most. According to a report by the International Federation of Robotics, industries utilizing advanced automation technologies have seen productivity improvements between 20-25%. Such data emphasizes the importance of evaluating your current technological landscape and understanding the advances that can aid in streamlining operations. For instance, a deep dive into automation capabilities and predictive maintenance features could significantly influence equipment selection, ensuring the longevity and reliability of machinery within your specific industry context. By aligning machinery choices with precise needs and industry standards, companies can foster sustainable growth and achieve competitive advantages.

Evaluating the Quality and Reliability of Euro Machinery Suppliers

When selecting Euro machinery for your industry, one of the most critical aspects is evaluating the quality and reliability of suppliers. A reliable supplier not only delivers high-quality machinery but also stands behind their products with excellent customer support. Begin your assessment by examining the supplier's history and reputation in the industry. Look for reviews or testimonials from previous clients, as these can provide insights into their reliability and service quality.

Tip: Investigate whether the supplier holds relevant certifications or quality assurance marks. These accreditation can indicate compliance with international standards and suggest a commitment to quality control, making them more likely to provide machinery that meets your specific needs.

Additionally, it's essential to consider the supplier's responsiveness and communication style. Effective communication can significantly impact your purchasing experience, especially regarding custom orders or technical support.

Tip: Ask potential suppliers about their after-sales service policies. A strong after-sales support system ensures that you will receive assistance in case of machinery malfunctions or needed maintenance, ultimately reducing downtime and enhancing productivity. By focusing on these factors, you can make a more informed decision when choosing a Euro machinery supplier.

Cost Analysis: Balancing Price and Performance in Machinery Selection

When selecting machinery for your industrial operations, a thorough cost analysis is essential for achieving the right balance between price and performance. According to a report by the International Federation of Robotics, the average return on investment (ROI) for industrial machinery can range from 20% to 30%, significantly influenced by the initial purchase price versus operational efficiency over time. Choosing machinery solely based on upfront costs may lead to higher maintenance costs and suboptimal productivity in the long run, highlighting the importance of evaluating TOTAL COST OF OWNERSHIP (TCO).

To perform an effective cost analysis, it's crucial to consider not just the initial investment but also factors such as energy consumption, maintenance frequency, and downtime. Research from the Machinery and Equipment Manufacturers Association (MEMA) indicates that machinery with higher initial costs often employs advanced technology that can deliver greater energy efficiency and lower operational costs, often recouping the initial investment within a few years. Furthermore, adapting machinery to specific operational needs can enhance performance, which, when quantified, can justify a higher price tag if it leads to increased throughput and product quality.

Balancing price with these performance aspects will ultimately support sustainable growth in your industry.

Importance of After-Sales Support and Service in Machinery Choices

When selecting machinery for industrial use, the importance of after-sales support and service often cannot be overstated. Choosing equipment that comes with robust after-sales assistance can significantly impact operational efficiency and overall productivity. A strong support system ensures that any potential issues can be quickly addressed, minimizing downtime and keeping production schedules on track. Effective after-sales service includes readily available technical assistance, timely repairs, and routine maintenance, all of which contribute to the longevity and reliability of the machinery.

Moreover, the presence of comprehensive after-sales support can be a decisive factor in differentiating between similar machinery options. Companies that prioritize customer service demonstrate a commitment to their client’s success, building a relationship that extends beyond the initial purchase. This relationship fosters trust and can provide valuable insights for future upgrades or product selections as the business evolves. Therefore, when evaluating potential machinery, it is crucial to investigate the after-sales service offerings and consider how they align with your operational needs and long-term goals.

Related Posts

-

Top 5 CNC Machine Auctions in 2023: Unlocking Huge Savings and Opportunities

-

Top 5 Must Have Construction Machines for Every Builder

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

What is Machinery Parts and Their Importance in Modern Manufacturing

-

How to Find the Best Deals at Machine Tool Auctions with Industry Insights

-

2025 Guide: How to Choose the Best Extruder Machine for Your Needs