10 Essential Tips for Choosing Machinery and Equipment in Your Business?

Choosing the right machinery and equipment for your business is crucial. It directly impacts efficiency, productivity, and ultimately, success. The vast array of options available can be overwhelming. Businesses must consider their specific needs and budgets carefully.

Every industry has unique requirements that dictate the type of machinery and equipment to invest in. For example, construction firms need robust machines, while manufacturers might focus on precision equipment. Mistakes in this area can lead to costly setbacks. A wrong choice can mean wasted resources and lost time.

It's essential to evaluate factors like reliability and support. Is the machinery user-friendly? How available are spare parts? Are the operation costs manageable? Reflecting on these questions can help refine your choices. Ultimately, the right selection of machinery and equipment sets the foundation for a thriving business. Each decision should be backed by careful thought and consideration.

Understanding Your Business Needs for Machinery and Equipment

Understanding your business needs for machinery and equipment is crucial for success. Assess your current operations. Identify which tasks require mechanization. This step helps streamline processes. According to a report by the National Association of Manufacturers, businesses that carefully select machinery can see a productivity increase of up to 30%. However, many companies overlook this crucial phase.

Next, consider future growth. Will your business expand in size? Make sure your equipment can accommodate changes. Flexibility in machinery may cost more upfront, but it saves money long-term. According to industry analysis, 40% of businesses regretted underestimating future requirements. This miscalculation led to costly upgrades later.

Budget constraints always come into play. Align your machinery choices with financial realities. It’s tempting to choose based on brand or popularity. Yet, often, less-known options outperform higher-priced counterparts. This inconsistency is where reflection is necessary. Evaluate several choices. Rely on industry data and testimonials to guide your decision-making. A well-informed choice will pay dividends in productivity and efficiency.

10 Essential Tips for Choosing Machinery and Equipment in Your Business

This chart illustrates the importance of various factors when selecting machinery and equipment for your business needs. The factors evaluated include Cost, Efficiency, Maintenance, Durability, and Technology.

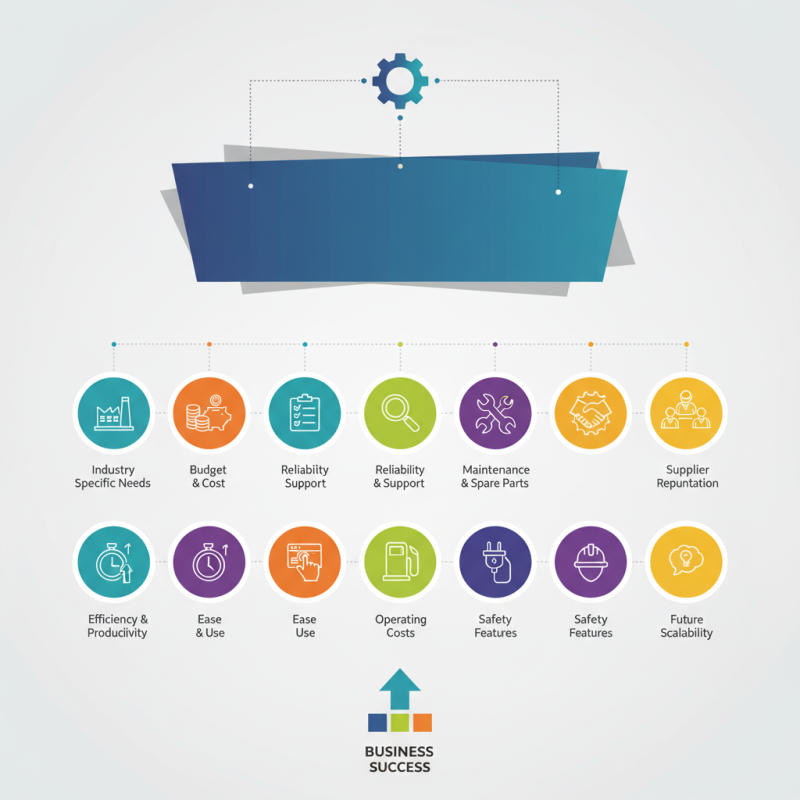

Evaluating Specifications: Key Features to Consider

When evaluating machinery and equipment for your business, specifications are critical. Key features can determine efficiency and productivity. According to a report by the Association for Manufacturing Technology, nearly 70% of manufacturers reported improvements after upgrading to more advanced machinery. This highlights the importance of selecting equipment with the right capabilities.

Consider the type of tasks your machinery will perform. Look for performance specifications. Speed, accuracy, and power are essential. For instance, in the automotive sector, a machine that operates at higher RPMs can significantly reduce production time. However, high speed may come at the cost of precision. Balancing these features requires careful thought.

Another aspect is durability. The average lifespan of industrial machinery can vary widely. Some equipment may last under five years, while others can exceed twenty. Data indicates that poorly chosen machinery often requires replacement sooner than expected. Investing time in evaluating these specifications can save costs in the long run. Making informed decisions not only enhances productivity but also helps avoid the pitfalls of increased downtime and repair expenses.

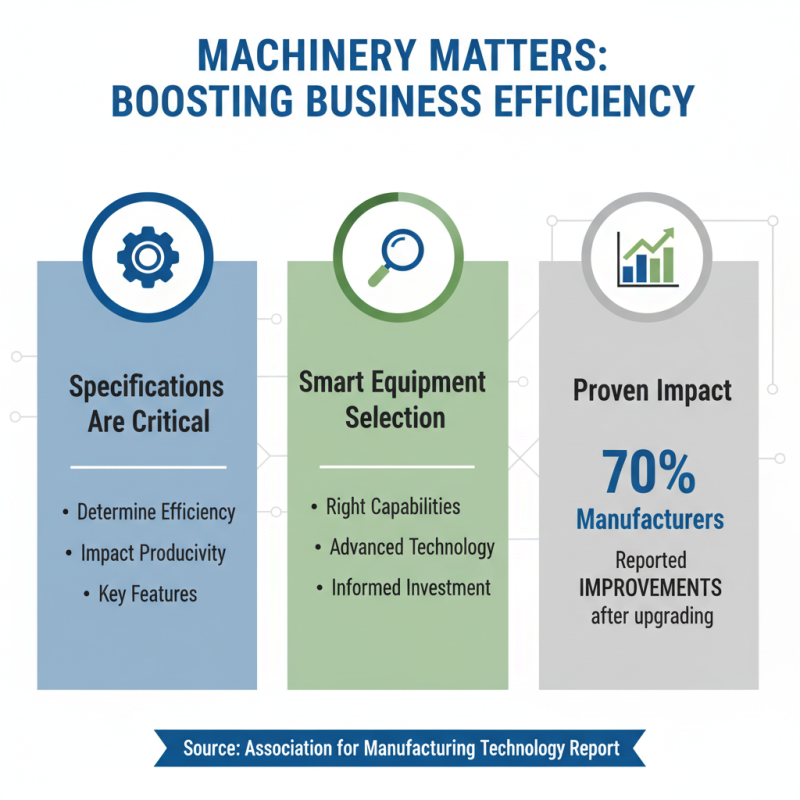

Assessing Budget and Cost-Effectiveness for Equipment Choices

When investing in machinery and equipment, assessing the budget is crucial. The manufacturing sector suggests that equipment costs often consume 30% to 50% of operational budgets. Allocating funds effectively can drive profitability. A well-planned budget can help avoid unnecessary expenses.

Consider the total cost of ownership, not just the initial purchase price. This includes maintenance, repair, and potential downtime costs. Studies show that machinery can incur up to 20% of its total cost in maintenance each year. Identifying reliable vendors and quality machines can mitigate these ongoing expenses.

Tip: Evaluate different financing options. Leasing may be a better fit for your cash flow. Buying might seem cheaper but can strain resources. Assess your business needs critically before making a decision. A misstep here can lead to regret later. Analyze how each purchase aligns with your long-term goals. Remember, it’s about making choices that provide value and boost efficiency.

Researching Manufacturers and Supplier Reputation

When selecting machinery and equipment for your business, the reputation of manufacturers and suppliers is crucial. A recent industry report indicates that nearly 70% of businesses prioritize supplier reliability when making purchases. This statistic underscores the importance of researching potential partners thoroughly. Look for reviews and testimonials that reflect their performance in the market. Past clients often share valuable insights on the equipment’s durability and the supplier’s customer service.

Consider the financial stability of manufacturers too. A strong financial background often correlates with consistent product quality. According to the Machinery Manufacturer Survey, 55% of buyers reported issues with machinery that failed after a short period. This can often be traced back to selecting less reputable suppliers. Take the time to validate any claims about product efficiency. Ask for case studies or references from similar companies. Doing your due diligence here will save you from expensive mistakes and unreliable equipment in the long run.

It’s also essential to reflect on your own needs. While you may be drawn to a manufacturer with a flashy website, it’s vital to assess the actual performance of their products. Sometimes, their reputation might not align with actual user experiences. Look for a balance between market presence and proven reliability to ensure your investment pays off.

10 Essential Tips for Choosing Machinery and Equipment in Your Business

| Tip Number | Tip | Importance Level | Considerations |

|---|---|---|---|

| 1 | Assess Your Needs | High | Determine the specific tasks and production volumes. |

| 2 | Research Manufacturers | High | Look for established brands with solid reputations. |

| 3 | Check Reviews and Testimonials | Medium | Assess customer feedback on performance and reliability. |

| 4 | Evaluate Warranty Options | Medium | Understand the coverage and terms offered. |

| 5 | Consider Total Cost of Ownership | High | Factor in maintenance, operation, and training costs. |

| 6 | Analyze Energy Efficiency | Medium | Higher efficiency can lead to cost savings. |

| 7 | Assess Support and Service | High | Consider availability of local service and parts. |

| 8 | Look for Scalability | Medium | Choose machines that can grow with your business. |

| 9 | Visit Trade Shows | Low | Interact with manufacturers to see machines firsthand. |

| 10 | Seek Expert Advice | Medium | Consult industry experts for insights and recommendations. |

Planning for Maintenance and Support Services in Equipment Selection

When selecting machinery and equipment, one critical aspect is planning for maintenance and support services. Understanding the maintenance needs upfront saves time and money. Choose equipment that has readily available support services. This ensures you receive preventive maintenance and quick repairs when needed.

Consider the ease of accessing spare parts. If parts take too long to arrive, your operations can suffer. It's wise to look for equipment with a track record of reliability. Research how often similar machines require repairs. A lower downtime can enhance productivity and profit.

However, not every choice is straightforward. Sometimes, companies opt for lower upfront costs. This can lead to more frequent repairs and higher long-term expenses. Reflecting on hidden costs is essential in making informed decisions. Think about the long-term implications of your choices before committing. That could save you both headaches and extra expenses later.

Related Posts

-

Top 5 Must Have Construction Machines for Every Builder

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

Essential Tips for Choosing Industrial Machinery That Boost Efficiency and Productivity

-

Top 10 Industrial Machinery Trends Shaping the Future of Manufacturing

-

How to Choose the Right Industrial Machinery for Your Business Needs in 2025

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025