2025 Guide: How to Choose the Best Extruder Machine for Your Needs

Choosing the right extruder machine is a crucial decision for businesses involved in manufacturing and production. As industries evolve, the demand for precise, efficient, and reliable equipment has never been more vital. The extruder machine is at the heart of many production processes, serving various applications from food processing to plastics and beyond. With an array of models and technologies available in 2025, understanding how to select the best extruder machine tailored to your specific needs can significantly impact your operational efficiency and product quality.

In this guide, we will explore the essential factors to consider when purchasing an extruder machine, including the type of materials you plan to process, desired output rates, and the specific characteristics that define quality performance. Whether you are a seasoned manufacturer or entering the market for the first time, having a comprehensive understanding of your requirements will enable you to make an informed choice. By the end of this guide, you will be equipped with the knowledge necessary to navigate the complexities of extruder machines, ensuring that you invest wisely in equipment that supports your business goals and enhances productivity.

Understanding Extruder Machines: Types and Functions

Understanding extruder machines is crucial for selecting the right one for your manufacturing needs. Extruder machines primarily fall into two categories: single-screw and twin-screw extruders.

Single-screw extruders are often more straightforward and suitable for simpler processes, such as plastic and food applications. In contrast, twin-screw extruders offer better mixing and allow for more complex operations, making them ideal for polymer blending and compounding.

When choosing an extruder, consider the specific functions you need it to perform. For instance, if your operation requires high output and mixing accuracy, a twin-screw extruder may be the better option. Additionally, take into account factors such as product viscosity and temperature requirements.

Tips: Ensure that the extruder you select can accommodate any future scaling or changes in your production process. It's also advisable to consult with manufacturers to understand the maintenance requirements and the availability of spare parts. Choosing the right machine can greatly enhance efficiency and product quality, so don’t rush the decision.

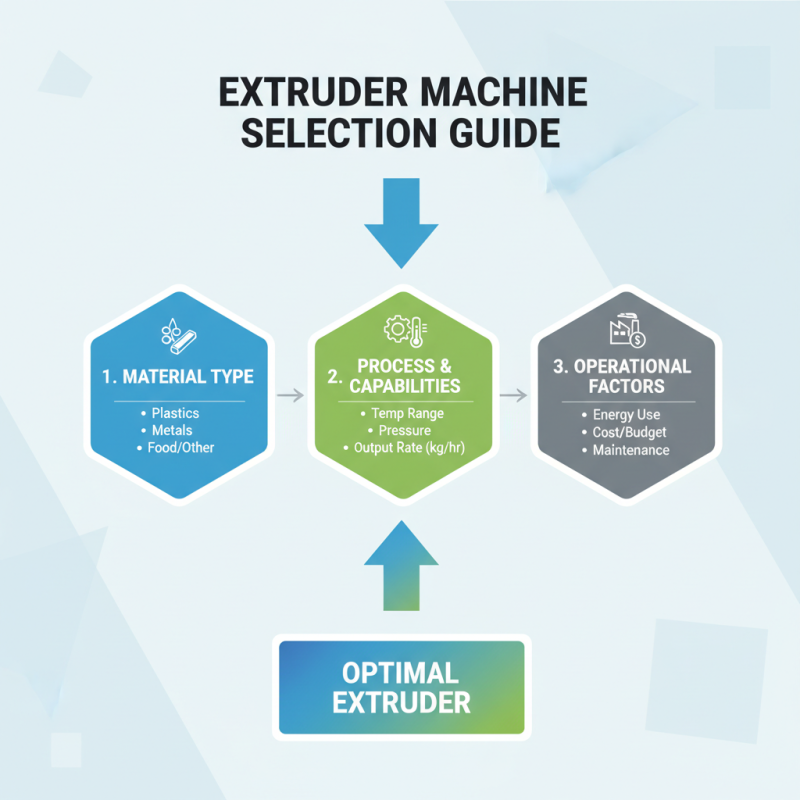

Key Factors to Consider When Choosing an Extruder Machine

When selecting the best extruder machine for your needs, there are several key factors to consider. First, the type of material you plan to extrude plays a crucial role in determining the right machine. Different materials, such as plastics, metals, or food items, require specific extrusion processes and machine capabilities. Assessing the compatibility of the machine with your material will ensure efficient production and reduce potential issues during operation.

Another essential aspect to evaluate is the machine's output capacity. Depending on your production volume requirements, you might need a machine capable of high throughput. It's important to balance the desired output with the machine's size and energy consumption to maximize efficiency.

**Tips**: Before making a purchase, conduct thorough research on various brands and models available in the market. This will help you compare features and pricing. Additionally, consider reaching out to current users of specific machines for firsthand insights on their performance and reliability. Being informed will empower you to make a decision that best aligns with your operational needs.

Assessing Your Production Needs and Material Compatibility

When selecting the best extruder machine for your production needs, assessing material compatibility is paramount. According to a report by Grand View Research, the global extrusion equipment market is projected to reach USD 4.4 billion by 2025, driven primarily by advancements in materials technology. This underscores the importance of not just considering the machine's capabilities but also the specific types of materials you plan to work with. Different extruders are designed for various materials, including thermoplastics, elastomers, and PVC, each requiring tailored settings to optimize performance and output quality.

Moreover, industry data from MarketsandMarkets indicates that the demand for customized extrusion solutions is on the rise, with over 60% of manufacturers seeking machines that can handle multiple materials efficiently. This trend highlights the necessity of choosing an extruder that offers versatility in material compatibility. Assessing your production needs, such as the volume of output and the specific properties required for your end products, will help in aligning your choice of equipment with your operational goals. The right extruder can significantly impact not only efficiency and cost-effectiveness but also the final quality of your products.

Evaluating Extruder Features: Capacity, Speed, and Efficiency

When choosing the best extruder machine for your needs, evaluating extruder features such as capacity, speed, and efficiency is paramount. According to a recent report by MarketsandMarkets, the global extrusion market is projected to reach USD 9.5 billion by 2025, growing at a CAGR of 5.2%. This growth emphasizes the importance of selecting machines that not only meet but exceed operational requirements in terms of volume and speed. For instance, extruders with a higher capacity can significantly reduce production time and costs, making them attractive options for high-demand industries.

Efficiency is another critical factor to consider. The Energy Efficiency Improvement Report by the U.S. Department of Energy highlights that modern extruder machines can achieve energy savings of up to 30% compared to older models. This efficiency not only contributes to lower operational costs but also supports sustainability initiatives within manufacturing processes. Investing in an extruder that offers advanced features such as variable speed drives and temperature control can enhance productivity while reducing waste and energy usage. These considerations ultimately lead to smarter investment choices when upgrading or purchasing new machinery.

2025 Guide: How to Choose the Best Extruder Machine for Your Needs - Evaluating Extruder Features: Capacity, Speed, and Efficiency

| Model | Capacity (kg/h) | Speed (RPM) | Efficiency (%) | Power Consumption (kW) | Dimensions (LxWxH, mm) |

|---|---|---|---|---|---|

| Model A | 200 | 150 | 85 | 55 | 3000 x 1200 x 1500 |

| Model B | 250 | 180 | 90 | 65 | 3200 x 1300 x 1600 |

| Model C | 300 | 200 | 88 | 75 | 3500 x 1400 x 1700 |

| Model D | 150 | 120 | 80 | 50 | 2800 x 1100 x 1400 |

Budgeting for Your Extruder Machine: Costs and Financing Options

When considering the purchase of an extruder machine, budgeting is a crucial step that can significantly impact your business's operational efficiency and profitability. According to a report by MarketsandMarkets, the global market for extrusion machinery is expected to grow from $5.6 billion in 2020 to $7.1 billion by 2025, highlighting the increasing demand and consequently competitive pricing in the industry. Depending on the specifications, the cost of an extruder machine can range from $15,000 to over $100,000. Thus, understanding financing options becomes essential for many businesses.

Financing options for extruder machines are diverse and can be tailored to meet specific business needs. Traditional bank loans, leasing agreements, and financing through equipment manufacturers are common methods. A survey by Equipment Finance Advisor shows that 71% of businesses prefer financing options that allow for flexible payment terms, indicating a growing trend toward leasing as it may preserve cash flow while enabling access to necessary technology. Additionally, government and industry-specific grants may provide financial relief for companies looking to invest in energy-efficient or innovative extruder solutions. This strategic approach to budgeting not only ensures that the machine meets operational demands but also aligns with financial goals.

Related Posts

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project

-

Top 5 Must Have Construction Machines for Every Builder

-

How to Find the Best Deals at Machine Tool Auctions with Industry Insights

-

Top 5 CNC Machine Auctions in 2023: Unlocking Huge Savings and Opportunities

-

What is Machinery Parts and Their Importance in Modern Manufacturing

-

Top 5 Second Hand Industrial Equipment Options for Your Business Needs