Why Heavy Construction Equipment Is Essential for Modern Infrastructure?

In today's rapidly evolving world, heavy construction equipment plays a pivotal role in shaping modern infrastructure. According to John Adams, an industry expert at Heavy Machinery Insights, "Without heavy construction equipment, our cities would struggle to grow." His insight highlights the importance of reliable machinery in urban development.

Heavy construction equipment facilitates the building of roads, bridges, and skyscrapers. These machines can lift immense loads and excavate vast areas of land, essential for any major project. However, despite their effectiveness, these machines also have their drawbacks. Downtime due to maintenance can slow progress. Moreover, the environmental impact of large machinery raises concerns.

As we advance into the future, the heavy construction industry must focus on innovation. Balancing efficiency with sustainability is a growing challenge. Embracing new technologies and practices is vital. The evolution of heavy construction equipment should focus on minimizing environmental footprints while maximizing output. The road ahead is filled with obstacles, but the potential for growth and improvement is immense.

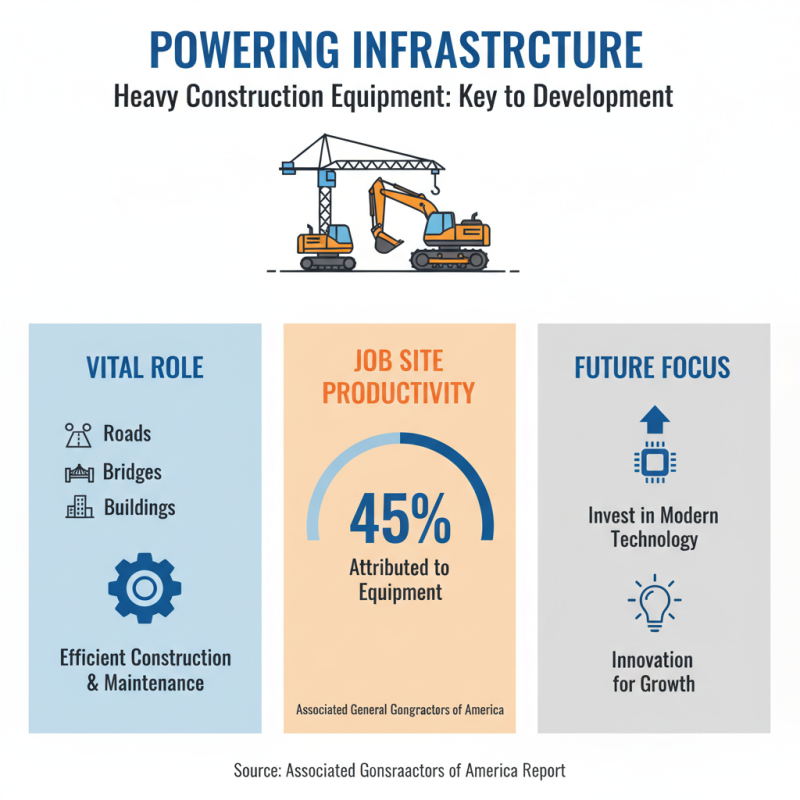

The Role of Heavy Construction Equipment in Infrastructure Development

Heavy construction equipment plays a vital role in infrastructure development. These machines enable efficient construction and maintenance of roads, bridges, and buildings. According to a report by the Associated General Contractors of America, construction equipment is responsible for nearly 45% of job site productivity. This impact underscores the importance of investing in modern technology.

Excavators, bulldozers, and cranes transform the landscape of cities. They streamline tasks that would take weeks if done manually. For instance, a modern excavator can move 80 tons of earth in a single hour. However, reliance on heavy machinery raises concerns about environmental impact and sustainability. Operators must balance efficiency with eco-friendly practices.

In recent years, the industry has seen a push for advanced machinery that reduces emissions. Reports indicate that integrating new technology can lower fuel consumption by up to 30%. Yet, adoption remains slow, as many operators hesitate to invest in high-tech alternatives. The future of infrastructure hinges on this dilemma, requiring thoughtful consideration of both innovation and implementation challenges.

Types of Heavy Construction Equipment and Their Functions

Heavy construction equipment plays a crucial role in building modern infrastructure. Various types of machines fulfill different functions, making tasks more efficient. Excavators, for example, dig deep trenches and remove dirt quickly. They are essential for foundation work. Bulldozers push large amounts of earth and are perfect for grading land. They can transform a rough site into a smooth area.

Crane trucks are vital for lifting heavy materials. They help position beams and other structures high above the ground. It's fascinating how they maneuver loads with precision. However, operators must undergo extensive training. Mistakes can lead to accidents on site, highlighting the importance of safety. Another key machine is the concrete mixer. It prepares concrete on-site, ensuring fresh material. Yet, improper mixing ratios can weaken the final structure.

Each piece of equipment has its own challenges. Operators need to ensure all machines are well-maintained. Breakdowns can halt progress and increase costs. The complexity of heavy construction machines mirrors the challenges in building effective infrastructure. Each function serves a purpose, but every task requires attention to detail. A single oversight can have lasting impacts.

Heavy Construction Equipment Types and Their Functions

The chart displays the number of units in use for various types of heavy construction equipment, illustrating their significance in modern infrastructure development. Excavators lead the way, followed closely by bulldozers and dump trucks, showcasing the varying roles these machines play in construction projects.

Impact of Heavy Equipment on Project Efficiency and Safety

Heavy construction equipment plays a pivotal role in enhancing project efficiency and safety. According to a report by the Association of Equipment Manufacturers, using advanced machinery can boost productivity by as much as 30%. Projects that employ heavy equipment are often completed faster. This increased speed can lead to significant cost savings and timely project delivery.

However, challenges still arise in equipment management. Not all operators are trained adequately, which can result in accidents. A study from the Bureau of Labor Statistics noted that improper operation causes up to 25% of construction site injuries. Ensuring operators are well-equipped with safety training is crucial. It’s important to continuously address these training gaps.

Site safety improves significantly with proper equipment usage. Equipment such as excavators and bulldozers helps create safer work environments. Yet, a report by the Construction Industry Institute showed that over 50% of construction accidents are due to human error. This indicates a persistent need for focused training and protocol adherence. Each job site presents unique challenges. Continuous reflection on safety practices must be prioritized.

Technological Advancements in Heavy Construction Machinery

Technology is revolutionizing heavy construction machinery. Advanced equipment enhances efficiency on job sites. Operators can accomplish tasks faster and with precision. For example, GPS technology allows for accurate grading and excavation. It minimizes human error and reduces wasted resources. The integration of drones offers aerial views for better planning.

Moreover, electric and hybrid machinery is becoming more common. These options lower emissions and fuel costs. However, they may require new skill sets for operators. Training programs evolve to meet these needs. Yet, some workers resist change, preferring traditional methods. This hesitation can slow down project timelines.

Remote-controlled machinery is also gaining traction. Operators can work from a safe distance, increasing site safety. However, reliance on technology can create vulnerabilities in case of failure. It's essential to have contingency plans in place. Embracing these advancements is crucial, but navigating the transition requires reflection and adaptation.

Sustainability Considerations in Heavy Equipment Usage for Infrastructure

Sustainability is a pressing concern for modern infrastructure projects. Heavy construction equipment plays a crucial role in this context. However, the ecological footprint of this machinery can be significant. Operators must consider fuel consumption, emissions, and noise pollution. Replacing diesel engines with electric alternatives can reduce these impacts. Still, electric equipment might not be feasible for every project.

Training operators is another vital aspect of sustainability. Well-trained workers can optimize the use of heavy machinery. This leads to less wasted fuel and reduced wear on equipment. Implementing a maintenance schedule helps. It ensures machinery runs efficiently and lasts longer. Yet, many companies overlook this step.

Material choices also affect sustainability. Using recycled materials can lessen the demand for new resources. But the integration of these materials into heavy construction requires careful planning. Projects might struggle without proper assessment. Emphasizing sustainable practices can foster community trust. It reflects a commitment to responsible development amid growing environmental concerns.

Why Heavy Construction Equipment Is Essential for Modern Infrastructure? - Sustainability Considerations in Heavy Equipment Usage for Infrastructure

| Equipment Type | Primary Use | Fuel Type | Average Emissions (g CO2/kWh) | Lifespan (Years) | Sustainable Alternatives |

|---|---|---|---|---|---|

| Excavator | Digging & Earth Moving | Diesel | 725 | 10-15 | Electric, Hybrid |

| Bulldozer | Land Clearing & Grading | Diesel | 793 | 10-15 | Electric, Biodiesel |

| Crane | Lifting & Moving Materials | Diesel / Electric | 600 | 15-25 | Electric, Hybrid |

| Dump Truck | Transporting Materials | Diesel | 814 | 10-15 | Compressed Natural Gas |

| Paver | Asphalt Laying | Diesel | 650 | 15-20 | Hydrogen, Electric |

Related Posts

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project

-

2026 Best Heavy Construction Equipment for Efficient Project Management?

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

2026 Top Construction Equipment Innovations You Need to Know?

-

Top Heavy Equipment Machinery Trends in 2026 What to Expect

-

2026 Best Heavy Machinery Trends to Watch for in the Industry?