Top 10 Industrial Machinery Trends Shaping the Future of Manufacturing

The industrial machinery sector is undergoing a transformative phase, driven by advancements in technology and evolving market demands. According to a report by the International Federation of Robotics, global spending on industrial robots is projected to reach $70 billion by 2025, signifying a robust shift towards automation that promises to reshape manufacturing processes. This trend not only enhances productivity but also paves the way for more sustainable practices within the industry.

As highlighted by Dr. Emily Carter, an industrial machinery expert at the Manufacturing Institute, “The integration of smart technologies in industrial machinery is not just a trend; it’s the foundation for the future of manufacturing.” Her insight emphasizes the critical role that innovations such as IoT (Internet of Things), AI (Artificial Intelligence), and data analytics play in optimizing operational efficiency and minimizing downtime. The convergence of these technologies is expected to revolutionize how manufacturers operate, making it essential for stakeholders to adapt and invest in these developing trends.

In this rapidly evolving landscape, it is crucial for industry leaders to stay informed about the latest innovations and shifts impacting industrial machinery. By embracing these trends, manufacturers can not only improve their competitiveness but also contribute to a more resilient and sustainable manufacturing ecosystem.

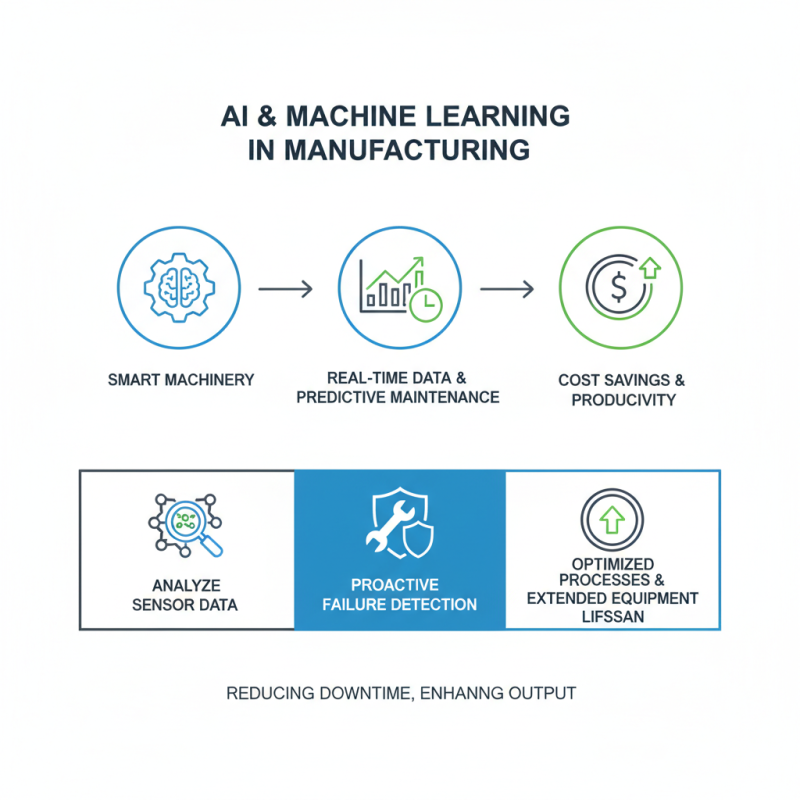

Emergence of Smart Manufacturing Technologies in Industrial Machinery

The emergence of smart manufacturing technologies is revolutionizing the landscape of industrial machinery, fostering a shift from traditional manufacturing processes to more integrated, automated solutions. At the heart of this transformation is the Internet of Things (IoT), which enables machines to communicate and exchange data seamlessly. This connectivity allows for real-time monitoring and predictive maintenance, significantly reducing downtime and increasing operational efficiency. By employing sophisticated sensors and data analytics, manufacturers can optimize production schedules and minimize waste, ultimately leading to enhanced productivity.

Moreover, the integration of artificial intelligence (AI) and machine learning algorithms in industrial machinery further propels smart manufacturing. These technologies analyze vast amounts of data collected from production lines to identify patterns and trends that humans may overlook. As a result, manufacturers can make informed decisions regarding resource allocation, product development, and quality control. This intelligent automation not only streamlines operations but also empowers human workers by providing them with advanced tools and insights, fostering a more collaborative environment in the manufacturing sector.

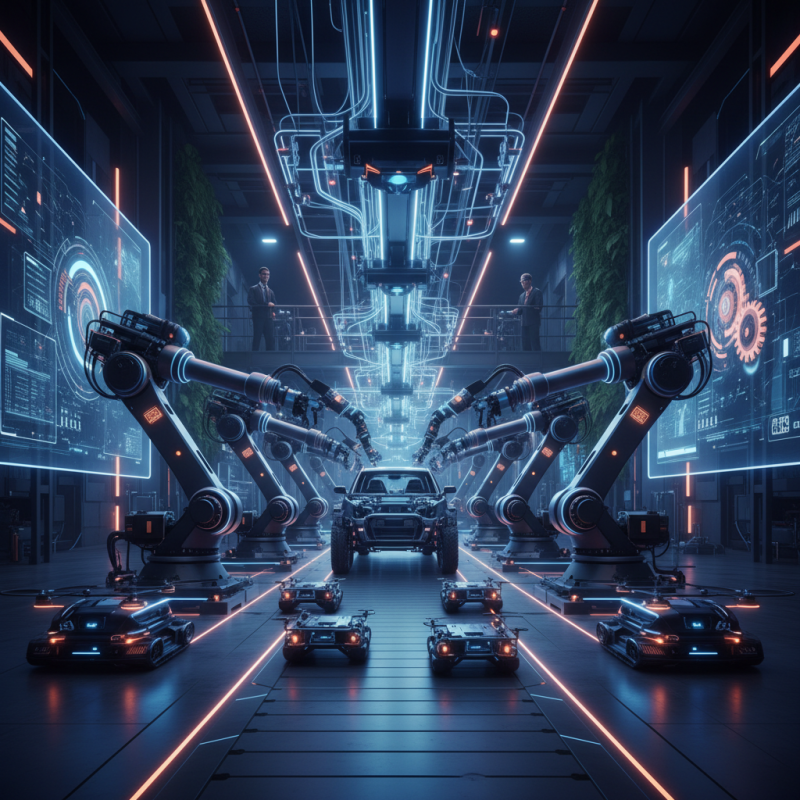

Integration of AI and Machine Learning for Process Optimization

The integration of artificial intelligence (AI) and machine learning in industrial machinery is redefining the landscape of manufacturing. This cutting-edge technology allows for real-time data analysis and predictive maintenance, enabling companies to optimize their processes significantly. AI systems can analyze vast amounts of data from machinery sensors, identifying patterns that may indicate potential failures before they occur. This proactive approach not only reduces downtime but also extends the lifespan of equipment, ultimately leading to cost savings and enhanced productivity.

Furthermore, the application of machine learning algorithms streamlines production workflows by adapting operations based on historical performance and current conditions. These algorithms can suggest adjustments to machinery settings, helping to fine-tune processes for maximum efficiency. As AI continues to evolve, its role in quality assurance becomes increasingly critical. By utilizing machine learning to detect anomalies during production, manufacturers can ensure consistent product quality while minimizing waste. Overall, the integration of AI and machine learning marks a transformative shift in the manufacturing sector, paving the way for smarter, more efficient operations.

Advancements in Robotics and Automation in Manufacturing

As manufacturing continues to evolve, advancements in robotics and automation are playing a crucial role in redefining productivity and efficiency. According to a recent report by the International Federation of Robotics (IFR), the global robotics market is forecasted to grow significantly, with an expected 20% increase in the number of industrial robots deployed by 2025. This surge is driven by the need for manufacturers to enhance operational efficiency and reduce costs, thereby making robotics an integral part of modern manufacturing facilities.

Robots are not merely taking over repetitive tasks; they are increasingly being integrated with artificial intelligence and machine learning capabilities. This allows for smarter operations, such as predictive maintenance and quality monitoring, which contribute to reduced downtime and waste. A study by McKinsey highlights that the adoption of automation in manufacturing could boost global productivity by up to 1.4 times faster by 2030, leading to substantial economic gains.

Tips: To leverage these advancements effectively, manufacturers should consider investing in collaborative robots (cobots) that can work alongside human operators. This enhances flexibility while maintaining safety. Additionally, training employees in robotics and automation technologies can significantly improve workforce adaptability, ensuring that they are prepared for the evolving demands of the manufacturing landscape. Embracing these changes will not only improve efficiency but also foster an innovative workplace culture.

Top 10 Industrial Machinery Trends Shaping the Future of Manufacturing

| Trend | Description | Impact on Manufacturing | Future Outlook |

|---|---|---|---|

| Increased Automation | The rise of automated processes to enhance efficiency and precision. | Reduces labor costs and errors, increases productivity. | Projected growth in adoption rates by 30% in the next 5 years. |

| Robotics Integration | Deployment of collaborative robots (cobots) alongside human workers. | Enhances worker safety and product quality. | Expected to see a 20% increase in usage across sectors. |

| AI and Machine Learning | Using AI for predictive maintenance and quality control. | Improves operational efficiency and reduces downtime. | Anticipated growth of 25% in implementation by 2025. |

| IoT in Manufacturing | Integration of IoT devices for real-time monitoring. | Enhances data collection and analytics. | Growth expected to reach 40% market penetration by 2026. |

| Smart Manufacturing | Leveraging advanced technologies for smarter production lines. | Increases flexibility and reduces waste. | Projected to grow in investment by 50% over the next decade. |

| 3D Printing | Use of additive manufacturing for rapid prototyping and production. | Reduces material waste and speeds up production cycles. | Expected to see a 30% rise in adoption by manufacturers. |

| Supply Chain Optimization | Integration of technology to improve the supply chain efficiency. | Enhances logistics and reduces operational costs. | Projected advancements in logistics technology by 35%. |

| Sustainability in Manufacturing | Focus on eco-friendly processes and materials. | Reduces environmental impact and enhances brand value. | Growth in demand for sustainable practices by 40%. |

| Cybersecurity Measures | Increased focus on protecting manufacturing systems from cyber threats. | Safeguards sensitive data and operational integrity. | Investments expected to rise by 50% in the next few years. |

Growth of Sustainable and Eco-Friendly Machinery Solutions

The shift toward sustainable and eco-friendly machinery solutions is becoming a defining trend in the manufacturing sector. As industries face increasing pressure to minimize their environmental footprint, manufacturers are innovating by adopting green technologies and materials. This move is not just a response to regulatory requirements but also a recognition of the economic advantages that sustainable practices can bring. Energy-efficient machines and renewable energy sources are central to this transformation, significantly reducing operational costs while aligning corporate strategies with environmental stewardship.

The integration of sustainable design principles into machinery production is also enhancing resource efficiency. From the use of recycled materials to the implementation of modular designs that facilitate easy upgrades and repairs, manufacturers are finding that sustainability can go hand in hand with productivity. Furthermore, the development of smart machinery that leverages IoT and AI enables real-time monitoring of energy consumption and waste generation, offering companies the insights needed to operate more sustainably. As these eco-friendly practices become more widespread, they are not only reshaping the industrial landscape but also fostering a culture of sustainability that benefits both manufacturers and the planet.

Impact of Industry 4.0 on Supply Chain and Production Efficiency

The impact of Industry 4.0 on supply chains and production efficiency is profound, marking a significant transformation in manufacturing operations. By integrating advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics, manufacturers can achieve heightened levels of real-time visibility and responsiveness throughout their supply chains. These technologies facilitate genuine connectivity between machines, products, and processes, enabling manufacturers to monitor and optimize operations continuously. As a result, businesses can predict demand fluctuations more accurately, adjust production schedules dynamically, and minimize waste, all of which contribute to enhanced productivity and cost efficiency.

Moreover, Industry 4.0 empowers manufacturers to adopt more agile and flexible production strategies. With the ability to analyze vast amounts of data swiftly, companies can make informed decisions that lead to improved inventory management and resource allocation. This results in streamlined operations, where production lines can shift quickly to accommodate varying customer demands without incurring significant downtime or excess labor costs. The emphasis on smart factories not only enhances operational efficiency but also fosters innovation, encouraging manufacturers to explore new business models and collaboration opportunities within their supply chains. Ultimately, the convergence of Industry 4.0 technologies is reshaping the production landscape, making it more resilient and adaptive to the complexities of modern markets.

Related Posts

-

Essential Tips for Choosing Industrial Machinery That Boost Efficiency and Productivity

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

Top CNC Machine Auctions: How to Find the Best Deals and Tips for Bidders

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

Why Choose an Equipment Trader: Benefits for Buyers and Sellers in Construction

-

What is Machinery Parts and Their Importance in Modern Manufacturing