Why You Should Invest in a Plastic Recycling Machine for Your Business

Investing in a plastic recycling machine is not just a forward-thinking move for your business; it represents a critical commitment to sustainability and economic efficiency. As global awareness about plastic pollution rises, industries are increasingly recognizing the necessity to incorporate recycling practices into their operations. According to Dr. Emily Harris, a leading expert in waste management and recycling technologies, “Adopting a plastic recycling machine is a strategic step that transforms waste into valuable resources while contributing to a circular economy.”

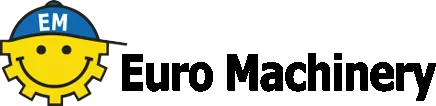

Businesses that embrace this technology can significantly reduce their environmental footprint while tapping into new revenue streams. Plastic recycling machines can be used to process post-consumer waste, transforming potential pollutants into reusable materials, thereby supporting the growing demand for recycled products. Moreover, making this investment aligns with regulatory trends and consumer preferences favoring sustainable practices, thus enhancing brand reputation and opening doors for new market opportunities.

In an era where sustainability is not just an option but a necessity, integrating a plastic recycling machine into your business model is not merely about compliance; it’s about leading the charge towards environmental responsibility and operational efficiency. The future of business lies in smart investments that prioritize both profit and planet, making the choice to invest in a plastic recycling machine more important than ever.

Benefits of Investing in a Plastic Recycling Machine for Your Business

Investing in a plastic recycling machine can significantly benefit your business by not only enhancing sustainability but also saving costs and creating new revenue streams. As environmental awareness grows, consumers are gravitating toward companies that demonstrate commitment to green practices. By incorporating plastic recycling into your operations, you can reduce waste and bolster your brand’s reputation, attracting environmentally conscious customers who prioritize sustainable products.

Moreover, a plastic recycling machine can lead to substantial cost savings. Instead of purchasing new plastic materials for production, businesses can recycle their waste plastic to create raw materials. This not only minimizes operational costs but can also provide a competitive edge in pricing against companies that rely entirely on virgin materials. Additionally, turning waste into valuable resources can transform a liability into an asset, enhancing your bottom line.

**Tip:** Start by conducting an audit of your current plastic usage and waste generation. Understanding your baseline can help you determine the size and type of recycling machine that best fits your businessneeds.

**Tip:** Consider partnering with local organizations or businesses engaged in sustainability initiatives. Such partnerships can amplify your recycling efforts and increase community support, showcasing your business as a leader in responsible practices.

Benefits of Investing in a Plastic Recycling Machine

Understanding the Different Types of Plastic Recycling Machines Available

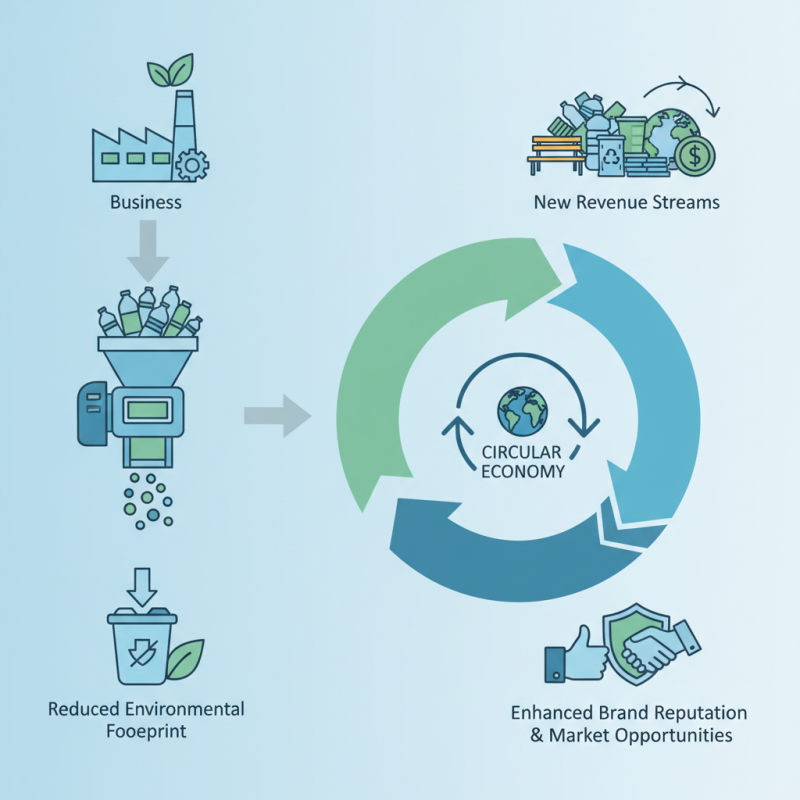

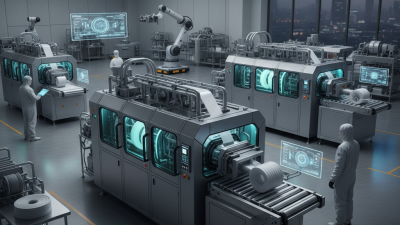

When considering the investment in a plastic recycling machine, it's essential to understand the various types available to determine which best fits your business's needs. One common type is the plastic granulator, which processes plastics into small granules that can be reused. This machine is particularly effective for recycling post-consumer waste, such as bottles and containers, and is often used in manufacturing settings where consistency in material quality is crucial.

Another option is the extruder, which melts plastic and shapes it into new products. This type of machine is ideal for businesses looking to produce specific items or components from recycled plastics. Additionally, there are blow molding machines designed for creating hollow plastic products like bottles and containers directly from recycled material. Each of these machines offers unique benefits, enabling businesses to tailor their recycling processes to their operational goals and the types of plastic they most commonly encounter. By understanding these different machines, businesses can optimize their recycling efforts and contribute to a more sustainable environment.

Key Factors to Consider When Choosing a Plastic Recycling Machine

When considering the investment in a plastic recycling machine, several key factors should be taken into account to ensure the success of your business endeavor.

The machine's production capacity is essential; according to a report by Smithers Pira, the global plastics recycling market is expected to exceed $40 billion by 2027, driven by increased environmental awareness and legislation.

Thus, selecting a machine with the right capacity for your projected output can greatly impact your operational efficiency and profitability.

Another critical aspect is the type of plastic your operation will focus on recycling.

Different machines are designed for various plastic types, such as PET, HDPE, or PVC.

The Society of the Plastics Industry highlights that recycling rates for plastics are still low, with only 9% of plastic waste being recycled globally.

Therefore, by choosing a machine that accommodates the specific types of plastics prevalent in your local area—or in demand within the recycling market—you can better align your business with industry trends and consumer needs.

Additionally, energy efficiency is key; investing in machinery with lower energy consumption can not only reduce your operational costs but also enhance your sustainability credentials.

How a Plastic Recycling Machine Can Improve Your Business Sustainability

Investing in a plastic recycling machine can significantly enhance your business's sustainability efforts. By incorporating such a machine into your operations, you can transform plastic waste into reusable materials, ultimately reducing your environmental footprint. This not only demonstrates corporate responsibility but also aligns your business with the growing global emphasis on sustainable practices. Adopting in-house recycling can lead to lower waste disposal costs and minimize reliance on external recycling services, providing a more efficient and eco-friendly solution.

Moreover, integrating a plastic recycling machine fosters a circular economy within your business ecosystem. It allows for the collection and processing of plastic waste generated from production, packaging, and other business activities. By recycling this material, you can create new products or materials, which can be sold or utilized within your operations, thereby enhancing resource efficiency. This approach not only attracts environmentally-conscious consumers but can also improve your brand's reputation, giving you a competitive edge in a market increasingly driven by sustainability.

Financial Implications of Owning a Plastic Recycling Machine

Investing in a plastic recycling machine can significantly influence the financial health of your business. By integrating such a machine, companies can reduce waste disposal costs and turn plastic waste into valuable raw materials for production. This approach not only enhances the sustainability profile of the business but also opens up new revenue streams through the sale of recycled materials. In many cases, businesses can recover their initial investment within a few years due to reduced costs and additional income.

Before making such an investment, consider the following tips: First, assess your business's plastic waste generation and your local recycling market to ensure a steady supply of input and a demand for outputs. Second, factor in maintenance and operational costs; a well-maintained machine can lead to higher efficiency and lower downtime. Lastly, explore potential tax incentives or grants for businesses that promote sustainability. These financial aids can help offset initial costs and improve overall returns on your investment.

Moreover, businesses should evaluate partnership opportunities with local governments or environmental organizations. Such collaborations can lead to shared marketing efforts, increased visibility, and even financial support. Committing to recycling not only benefits your bottom line but also enhances your company's reputation as an environmentally responsible player in the market.

Why You Should Invest in a Plastic Recycling Machine for Your Business - Financial Implications

| Dimension | Value |

|---|---|

| Initial Investment Cost | $50,000 |

| Annual Maintenance Cost | $3,500 |

| Expected Annual Revenue from Recycled Plastics | $100,000 |

| Payback Period | Less than 2 years |

| Potential Tax Credits | Up to $10,000 |

| Job Creation Potential | 5-10 jobs |

Related Posts

-

Top 5 CNC Machine Auctions in 2023: Unlocking Huge Savings and Opportunities

-

How to Choose the Right Metal Working Machines for Your Projects

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

How to Choose the Right Heavy Equipment Broker for Your Needs

-

2025 Guide: How to Choose the Best Extruder Machine for Your Needs

-

Top 5 Second Hand Industrial Equipment Options for Your Business Needs