Why Are Machine Tools Essential for Modern Manufacturing?

Machine tools play a pivotal role in modern manufacturing. They shape materials into precise parts and components. Renowned industry expert Dr. Emily Carter once stated, "Without machine tools, we would struggle to create the advanced products we rely on today." This underlines the significance of machine tools in our daily lives.

The evolution of manufacturing hinges on the advancements in machine tools. From simple lathes to complex CNC systems, these tools enhance productivity. However, not every facility adopts the latest technologies, creating a gap in efficiency. Some manufacturers still rely on outdated machine tools, which can hinder progress and innovation.

Investing in machine tools is crucial for staying competitive. Yet, the cost can deter some businesses from upgrading their equipment. Inadequate training on new machine tools is another challenge. Companies need to address these issues to harness the full potential of their machinery. Ultimately, the impact of machine tools on modern manufacturing cannot be overlooked. They are essential for driving innovation and efficiency.

The Evolution of Machine Tools in Modern Manufacturing Systems

Machine tools have undergone significant evolution over the decades. They are now central to manufacturing systems. According to a report by Deloitte, the machine tool market was valued at around $80 billion in 2020. This figure is expected to grow as industries adopt automation and precision manufacturing.

Automation technologies have transformed traditional machine tools. CNC (Computer Numerical Control) systems allow for high precision and efficiency. They reduce human error and enhance productivity. A study by the American Society of Mechanical Engineers highlights that CNC machines can improve production rates by up to 30%. However, issues like program errors or mechanical failures still arise. Not every operator is fully trained to handle complex machinery. This gap can lead to downtime and increased costs.

Moreover, the integration of IoT (Internet of Things) in machine tools represents both innovation and challenges. Real-time monitoring increases efficiency, but requires a reliable internet connection. Vulnerabilities to cybersecurity attacks can pose risks. The 2022 Cybersecurity & Infrastructure Security Agency report emphasized that manufacturing remains a high-risk sector. Embracing these advancements is crucial, yet companies must remain vigilant.

Key Types of Machine Tools and Their Role in Production Efficiency

Machine tools are the backbone of modern manufacturing. These tools include lathes, milling machines, and CNC machines. They play a vital role in shaping materials into finished products. According to a report by the Association for Manufacturing Technology, over 70% of manufactured goods require some form of machining. This underscores their importance in production efficiency.

CNC machines stand out for their precision. They can produce complex parts with minimal human intervention. This technology has increased production speed by up to 60%. However, the initial setup and programming can be time-consuming. Manufacturers must invest time to train operators effectively. This can be a hurdle for smaller companies.

Tip: Ensure that your team is well-trained on machine tools. Regular training can minimize errors. Mistakes can be costly, leading to waste and delays.

Milling machines remain crucial for their versatility. They can handle various materials and create diverse shapes. However, their operation requires skill. An untrained operator may produce inconsistent quality. Regular maintenance is also necessary to keep them efficient. Neglecting this can lead to expensive downtimes.

Tip: Schedule frequent maintenance checks on all machine tools. This practice can extend their life and enhance production quality.

Why Are Machine Tools Essential for Modern Manufacturing?

This chart illustrates the production efficiency of key types of machine tools used in modern manufacturing processes. The efficiency is measured in percentage, showcasing the importance of these tools in enhancing production capabilities.

Impact of Advanced CNC Technology on Precision Engineering

The rise of advanced CNC technology has transformed precision engineering. In 2022, over 60% of manufacturing companies adopted CNC machines. This shift dramatically increased productivity and reduced human error. Today’s CNC machines can operate with precision up to 0.001 mm, making them vital for intricate projects.

However, the integration of CNC technology isn't flawless. Many workers face a steep learning curve when transitioning from traditional machining methods. Reports indicate that nearly 25% of operators struggle with programming these systems efficiently. Additionally, the reliance on automated machines raises concerns about job displacement in the sector.

Moreover, the initial investment in CNC technology can be daunting. Many businesses hesitate, fearing high costs with unpredictable return on investment. Although the long-term benefits are significant, some manufacturers have encountered hidden maintenance expenses. This complexity needs careful consideration before diving into the CNC world, highlighting the importance of strategic planning in modern manufacturing.

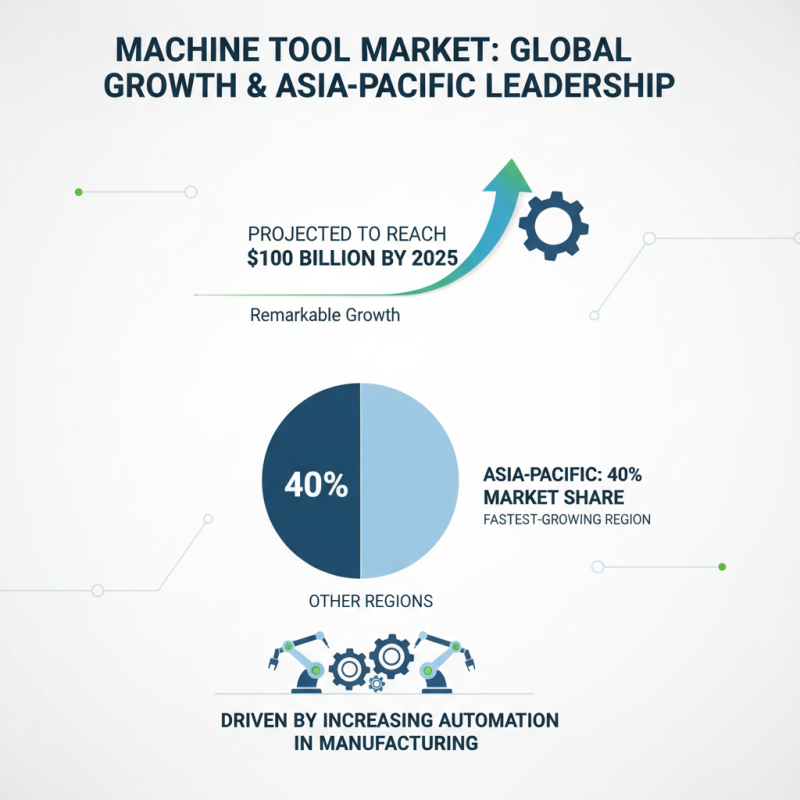

Statistical Data on Machine Tool Market Growth and Demand

The machine tool market is experiencing remarkable growth. According to recent industry reports, the global machine tool market is projected to reach USD 100 billion by 2025. This surge is driven by increasing automation in various manufacturing processes. Notably, Asia-Pacific is the fastest-growing region, accounting for nearly 40% of the market share.

Demand for precision and efficiency fuels this growth. In manufacturing, machine tools are vital for creating complex components with tight tolerances. Data shows that the aerospace and automotive sectors are the biggest consumers of these tools. In 2021, about 30% of machine tool sales were attributed to these industries. However, manufacturers face challenges in integrating advanced technologies. The skills gap among workers can slow down this integration.

While machine tools drive innovation, not everything is perfect. Many companies struggle to adapt to rapid technological changes. Current training programs may not adequately prepare workers. Reports suggest that 70% of manufacturers identify workforce development as a significant hurdle. This gap might hinder the potential growth of the machine tool sector in the coming years.

The Future of Machine Tools in Smart Manufacturing and Automation

The future of machine tools lies in smart manufacturing and automation. According to a recent report by McKinsey, global manufacturing productivity could increase by 20-30% with the integration of advanced technology. Machine tools are at the heart of this transformation. They enable precision and efficiency, crucial for meeting growing consumer demands.

However, the transition is not without challenges. Many manufacturers still rely on outdated machines. These machines are less efficient and can lead to increased downtime. A survey from Deloitte revealed that 40% of manufacturers lack effective digital strategies. This gap hinders their ability to embrace automation fully. Investing in modern machine tools can mitigate these issues.

Smart manufacturing employs IoT technology to create connected environments. Machine tools can communicate data on performance and maintenance. However, adoption rates remain low. In fact, only 30% of manufacturers are currently leveraging these technologies effectively. The path to fully automated factories requires commitment and continuous learning. Only then can manufacturers realize the full benefits of modern machine tools.

Why Are Machine Tools Essential for Modern Manufacturing? - The Future of Machine Tools in Smart Manufacturing and Automation

| Dimension | Value |

|---|---|

| Production Efficiency | 80% Increase |

| Reduction in Waste | 40% Decrease |

| Automation Integration Level | 70% of Operations |

| Cost Reduction | 30% Lower Production Costs |

| Tool Precision | ± 0.01 mm Accuracy |

| Maintenance Frequency | Once Every 6 Months |

Related Posts

-

10 Best Machine Tools for Precision Engineering?

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

10 Essential Tips for Choosing Machinery and Equipment for Your Business?

-

Top CNC Machine Auctions: How to Find the Best Deals and Tips for Bidders

-

2026 Best Heavy Machinery Trends to Watch for in the Industry?

-

What is Heavy Machinery and How is it Used in Industry?