2026 How to Select the Best Machinery Parts for Your Equipment?

Selecting the best machinery parts for your equipment is critical. Every piece plays a significant role in overall performance. Choosing the wrong parts can lead to inefficiencies and costly repairs. It is essential to consider specific factors to ensure optimal functioning.

Start by identifying the exact requirements of your machinery. Each machine has unique specifications that dictate which parts are suitable. Ignoring these details may result in poor compatibility. Assess the manufacturer’s recommendations as a foundational guideline. This step is often overlooked but is vital for successful operation.

Additionally, quality should never be compromised. Cheaper options might seem attractive, but they can lead to frequent breakdowns. Research various brands and read customer reviews. Look for parts that offer durability and reliability. It’s crucial to prioritize long-term performance over initial savings. Remember, the right machinery parts can enhance productivity and reduce downtime significantly.

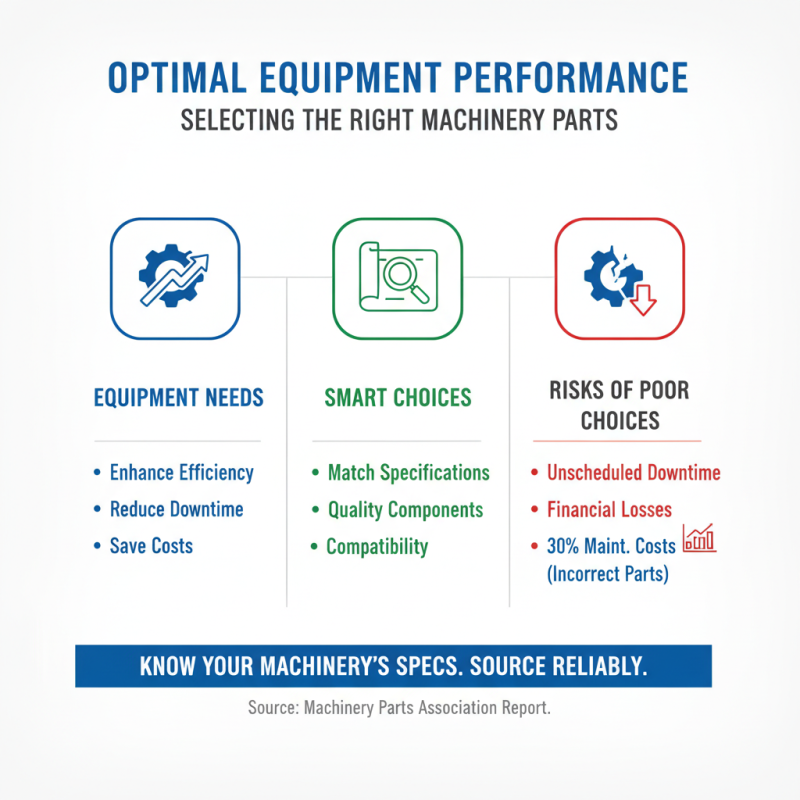

Understanding Your Equipment Needs: The Importance of Machinery Parts

Selecting the right machinery parts is essential for optimal equipment performance. Understanding equipment needs can significantly enhance efficiency. Poor choices may lead to unscheduled downtimes and financial losses. A report by the Machinery Parts Association indicates that up to 30% of maintenance costs arise from using incorrect components. Knowing your machinery’s specifications is critical.

It's important to assess usage patterns and operational demands. Some parts may wear out faster under heavy loads. Regularly monitoring equipment can help identify these needs. Consider performing routine checks to ensure parts meet performance requirements.

Tips: Always consult the equipment manual. This ensures proper specifications and compatibility. Evaluate multiple suppliers when sourcing parts. This can lead to better price comparisons and quality checks. Don't rush the selection process, as haste can lead to costly mistakes.

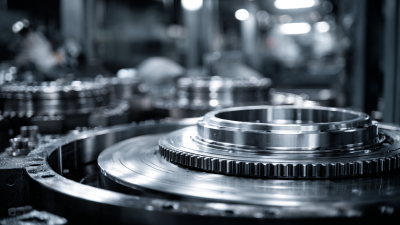

Factors to Consider When Choosing Machinery Parts for Equipment

When selecting machinery parts for equipment, several critical factors should be evaluated. Quality is paramount. According to a recent industry analysis, using high-quality parts can increase equipment lifespan by up to 30%. This directly impacts productivity and minimizes downtime. An overlooked detail is the compatibility of parts. Misalignments can lead to severe inefficiencies. Research indicates that up to 20% of machinery failures stem from incompatible components.

Cost-effectiveness also plays a significant role. A comprehensive report from the Machinery Association showed that long-term savings can be achieved by investing in reliable but slightly more expensive options. Many operators, however, are tempted to choose cheaper alternatives. This can lead to frequent replacements, ultimately costing more in the long run.

Moreover, sourcing from reputable suppliers is vital. It ensures that parts meet industry standards. A survey highlighted that 25% of machinery operators experienced issues due to subpar sourcing practices. Relying solely on price may not yield the best outcomes. Evaluating supplier reviews and feedback can provide insights into reliability. Awareness of these factors helps avoid unnecessary risks and reinforces operational efficiency.

2026 How to Select the Best Machinery Parts for Your Equipment?

| Factor | Description | Importance Level (1-5) | Examples |

|---|---|---|---|

| Compatibility | Ensure parts are compatible with your existing machinery. | 5 | Interchangeable parts, OEM specifications |

| Material Quality | Choose parts made from durable, high-quality materials. | 5 | Steel, aluminum, composites |

| Cost | Consider total cost, including installation and maintenance. | 4 | Initial price, long-term savings |

| Brand Reputation | Choose parts from reputable manufacturers to ensure reliability. | 4 | Industry reviews, customer feedback |

| Availability | Ensure parts are readily available to avoid downtime. | 3 | Local suppliers, online procurement |

| Warranty and Support | Check warranty terms and available customer support. | 4 | Replacement guarantees, technical support |

Evaluating Quality Standards for Machinery Parts Selection

Choosing the right machinery parts is crucial for optimal equipment performance. Quality standards should be your point of focus. Reports indicate that nearly 30% of machinery failures stem from subpar parts. This is a significant reason for considering quality during selection. An independent study highlighted that parts meeting ISO 9001 standards resulted in a 25% increase in machinery lifespan.

When assessing quality, examine the materials used. High-quality steel or aluminum often indicates durability. Look for certifications such as ASTM and SAE for specific applications; these ensure parts meet necessary specifications. Sometimes, even minor discrepancies can lead to major issues. For instance, a poorly manufactured bearing can escalate maintenance costs dramatically.

Moreover, it's essential to consider the supplier's reputation. According to recent industry surveys, 40% of companies reported difficulties in sourcing reliable parts. This reflects the challenges of maintaining quality standards. Remember, not all suppliers offer the same guarantees. Cross-checking reviews and feedback can guide better decisions.

In the end, emphasizing quality is not just about avoiding failure; it’s about enhancing overall efficiency.

Comparing Costs vs. Value: Making Informed Decisions

Choosing the right machinery parts is essential for optimal performance. Often, the focus is on costs. However, considering value is equally vital. Striking the right balance can lead to long-term savings and better efficiency.

When comparing costs, think deeply about the part's lifespan and performance. A cheaper part may save you money upfront. But if it wears out quickly, you’ll face higher replacement costs. Take time to analyze warranties and customer reviews. These factors can indicate whether a lower price is worth the risk.

**Tip**: Create a checklist. Include aspects like durability, compatibility, and service support. It will guide your decisions effectively.

Additionally, consider how parts affect your entire system. Sometimes, investing more can enhance overall productivity. For instance, a high-quality gearbox might boost efficiency, reducing energy consumption over time. Reflect on how initial spending can lead to savings later.

**Tip**: Evaluate long-term consequences. Don’t just look at immediate expenses. Think about maintenance costs over years.

Finding Reliable Suppliers for Machinery Parts: Tips and Resources

When selecting machinery parts, finding reliable suppliers is crucial. Data from the Machinery Suppliers Association indicates that about 70% of equipment failures stem from subpar parts. Therefore, a trusted supplier can make all the difference. Look for suppliers with a strong reputation in the industry. They often have rigorous quality control processes in place.

Tips: Verify certifications and ask for references. Direct feedback from other users can be invaluable. Additionally, consider suppliers who offer comprehensive warranties. This shows confidence in their products and commitment to customer satisfaction.

It's common to underestimate the importance of research. Many buyers focus only on cost, neglecting quality. Cutting corners can lead to increased downtime and repair costs. Remember, the cheapest option isn't always the best value. Balance your budget with quality demands to ensure longevity in your equipment performance.

2026 Machinery Parts Supplier Reliability Assessment

Related Posts

-

What is Machinery Parts and Their Importance in Modern Manufacturing

-

2025 Guide: How to Choose the Best Extruder Machine for Your Needs

-

2026 How to Choose the Right Earth Moving Equipment?

-

Why Choose an Equipment Trader: Benefits for Buyers and Sellers in Construction

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

Top 5 CNC Machine Auctions in 2023: Unlocking Huge Savings and Opportunities