Top 10 Textile Machinery Trends and Innovations for 2026

The textile machinery industry is on the brink of transformation as we approach 2026. Emerging technologies aim to enhance productivity and sustainability. According to a report by Global Market Insights, the textile machinery market is projected to exceed $30 billion by 2026, driven by growing demand for automation.

Experts emphasize the importance of innovation in this sector. For instance, Dr. Emily Henderson, a renowned textile machinery specialist, notes, "Adaptability to new technologies is crucial for the future of textile manufacturing." This statement highlights the need for companies to embrace change. Innovations like automated weaving machines and digital printing systems are reshaping production processes.

While the advancements promise increased efficiency, challenges remain. Companies must balance technological investment with workforce training. Moreover, not all innovations will have immediate benefits. The sector must reflect on the long-term impact of these trends on sustainability and job security in manufacturing. As the landscape evolves, staying informed about these key developments will be essential for success in the textile machinery industry.

Advancements in Digital Textile Printing Technologies by 2026

The textile industry is rapidly evolving, particularly in digital printing technologies. By 2026, these advancements will reshape production processes, enhancing efficiency and sustainability. According to a recent report, the digital textile printing market is projected to grow by over 20% annually. This growth highlights the increasing demand for high-quality, customized fabrics.

One significant trend is the development of eco-friendly inks. Traditional inks often contain harmful chemicals. New formulations, focusing on sustainability, reduce environmental impact. Innovations in printer technology also contribute. Faster print speeds and improved color accuracy are now achievable. However, transitioning to these technologies can be challenging. Many businesses struggle with the initial costs and training.

Tips: Embrace training programs for employees. This will help ease the transition to new technologies. Stay informed about the latest advancements. This knowledge is key to staying competitive. It's also important to assess your current infrastructure before investing. Not every organization is ready for a complete overhaul, and gradual updates often prove more effective.

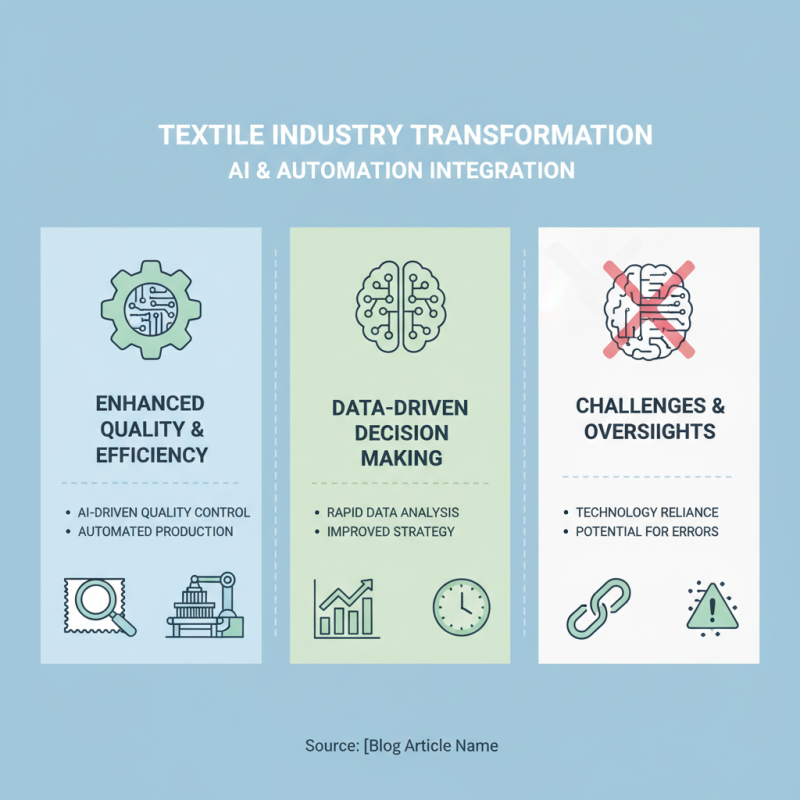

Integration of AI and Automation in Textile Manufacturing Processes

The textile industry is undergoing a significant transformation with the integration of AI and automation. This change is not without its challenges. Manufacturers are adopting AI-driven technologies to enhance quality control and production efficiency. Automated systems analyze data rapidly, improving decision-making processes. Yet, reliance on technology can sometimes lead to oversights.

Automation streamlines repetitive tasks, allowing workers to focus on creative aspects. However, the human touch remains essential. Textile design benefits from innovative tools, but machines can't replicate every nuance of craftsmanship. A balance between AI capabilities and human skills is crucial.

Moreover, the learning curve for implementing AI in manufacturing processes is steep. Many workforce members require training to adapt to new technologies. Miscommunication can occur during this transition. Companies need to remain patient and foster a supportive environment. The synergy between AI and human expertise will shape the future of textile manufacturing.

Sustainable Practices: Innovations in Eco-Friendly Textile Machinery

The textile industry is rapidly evolving towards sustainable practices. Innovations in eco-friendly textile machinery are leading the way for a greener future. Reports indicate that 80% of textile waste comes from production processes. This alarming statistic highlights the need for significant change.

New machinery designs focus on reducing water and energy consumption. Recent studies show that innovative dyeing technologies can cut water use by 50%. These advancements are essential for meeting the growing demand for environmentally-friendly products. Brands increasingly seek sustainable solutions to align with consumer values.

Tips: Consider investing in machinery that uses recycled materials. This can lower your environmental impact. Embrace automation to optimize production efficiency. It might seem costly upfront, but long-term savings can be significant.

Another emerging trend is the use of biodegradable textiles. Machinery that supports this innovation is becoming crucial. However, the transition to sustainable methods can be challenging. Not all manufacturers are ready for this shift. Some may need more time to adapt to new processes. It's a complex journey, but necessary for future resilience.

Top 10 Textile Machinery Trends and Innovations for 2026 - Sustainable Practices: Innovations in Eco-Friendly Textile Machinery

| Trend | Description | Impact on Sustainability | Projected Adoption Rate (%) |

|---|---|---|---|

| Biodegradable Fibers | Development of fibers that decompose naturally. | Reduces landfill waste and pollution. | 60% |

| Energy-Efficient Machinery | Machines designed to minimize energy consumption. | Lowers carbon footprint in production processes. | 75% |

| Waterless Dyeing Technology | Dyeing processes that eliminate the use of water. | Conserves water resources significantly. | 50% |

| Digital Textile Printing | Prints directly onto fabric, minimizing waste. | Enhances precision and reduces material waste. | 70% |

| Recycled Materials | Using recycled plastics and textiles in production. | Lowers dependence on virgin materials. | 65% |

| Automated Quality Control | Systems using AI to assess fabric quality. | Reduces waste by improving defect detection. | 55% |

| Sustainable Supply Chains | Focus on ethical sourcing and production. | Promotes responsible consumption and production. | 80% |

| Smart Textiles | Textiles that incorporate technology for functionality. | Enhances product lifespan and reduces waste. | 40% |

| AI in Design Process | Artificial Intelligence used to optimize design. | Enhances resource efficiency and innovation. | 62% |

| Traceability Solutions | Technology to track the origin of materials. | Ensures transparency and ethical practices. | 68% |

The Growth of Smart Textiles and Their Impact on the Machinery Market

The rise of smart textiles is transforming the textile machinery market. These innovative fabrics incorporate technology to enhance functionality. They can monitor body temperature, respond to environmental conditions, and even communicate with devices. This evolution is exciting but also poses challenges.

Manufacturers are investing heavily in equipment that supports these advancements. Machines are required to process new materials and integrate sensors seamlessly. However, adapting to these changes is not always straightforward. Many companies struggle with the learning curve involved in new production techniques. They face unexpected production delays and increased costs.

Moreover, sustainability remains a vital concern. Smart textiles often require additional resources for production. Balancing innovation with environmental responsibility is difficult. Companies must find ways to minimize waste while maximizing efficiency. This complex landscape calls for ongoing reflection and adaptation in the machinery sector. Embracing change is essential, but it also demands careful consideration.

Trends in Fiber Production: Innovations Driving Machinery Development

The textile industry is undergoing significant changes in fiber production. Innovations in machinery are essential for enhancing efficiency and sustainability. According to a report by MarketsandMarkets, the global textile machinery market is projected to reach $32 billion by 2026. This growth is driven by advancements in manufacturing processes and the demand for eco-friendly materials.

New fiber production technologies are emerging to meet market needs. For example, the use of recycled fibers is gaining traction. Research indicates that using recycled polyester in textiles can reduce carbon emissions by up to 70%. However, the integration of recycled materials into existing machinery poses challenges. Many machines may require upgrades or adjustments, leading to short-term inefficiencies.

The industry's push toward automation is notable. Automated systems can significantly improve production speed and consistency. However, implementing these technologies can be costly and complex. Companies must weigh the benefits against potential disruptions during the transition. As the industry advances, striking a balance between innovation and practicality remains critical.

Top 10 Textile Machinery Trends and Innovations for 2026

Related Posts

-

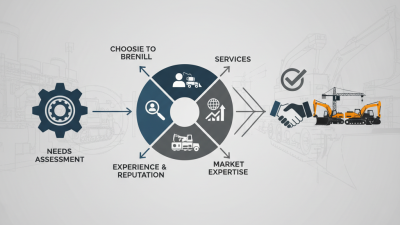

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

How to Choose the Right Industrial Machinery for Your Business Needs in 2025

-

What is Machinery Parts and Their Importance in Modern Manufacturing

-

How to Choose the Right Heavy Equipment Broker for Your Needs

-

Top CNC Machine Auctions: How to Find the Best Deals and Tips for Bidders

-

Top 10 Plant Machinery Types You Need to Know for Your Business