Essential Tips for Choosing Industrial Machinery That Boost Efficiency and Productivity

In the fast-evolving landscape of industrial operations, the selection of appropriate industrial machinery stands as a pivotal factor influencing both efficiency and productivity. According to a recent report by the International Association of Machinery Manufacturers, industries that invest in advanced machinery see a productivity increase of up to 30%. This remarkable statistic underscores the necessity for businesses to make informed choices when it comes to their machinery investments. As operational demands rise, the need for optimized processes has never been more critical.

Experts in the field, such as Dr. Alan Rutherford, a renowned industrial engineering consultant, emphasize the importance of aligning machinery selection with operational goals. Dr. Rutherford states, "Choosing the right industrial machinery is not just about immediate needs but also about future-proofing the business against evolving market demands." This insight highlights the growing importance of strategic planning in the procurement process. In this context, understanding the features, compatibility, and potential return on investment of industrial machinery becomes paramount. Properly selected machinery not only enhances production capabilities but can also lead to significant cost savings over time.

Factors to Consider When Selecting Industrial Machinery

When selecting industrial machinery, several key factors should be taken into account to ensure the equipment effectively enhances efficiency and productivity. First and foremost, consider the specific needs of your operations.

Evaluate the processes that the machinery will be involved in and identify the features necessary to meet those requirements. For instance, the capacity, speed, and overall compatibility with existing systems are critical elements that can significantly affect operational workflow.

Another important factor is reliability and maintenance. Opt for machinery that is known for its durability and ease of maintenance, as this can minimize downtime and repair costs. Investing in machinery with advanced technology can also improve reliability, as modern equipment often includes features that predict maintenance needs and reduce the likelihood of unexpected failures. Additionally, ensure that the machinery complies with safety standards and ergonomic considerations, which can enhance worker safety and overall productivity. By carefully assessing these factors, organizations can make informed decisions that lead to improved operational outcomes.

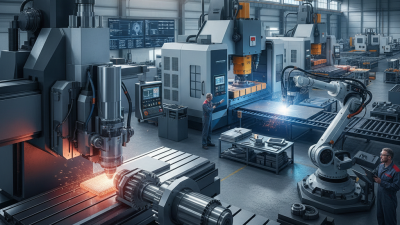

Understanding the Role of Technology in Enhancing Efficiency

When selecting industrial machinery, understanding the role of technology in enhancing efficiency is paramount. Advanced technologies such as automation, IoT, and machine learning can significantly streamline operations, minimize downtime, and improve production quality. These technologies enable real-time monitoring and adaptive control, which helps industries not only to maintain but also to optimize their equipment performance continuously. By integrating these tech-driven solutions, businesses can respond to market demands more swiftly, reduce waste, and increase overall productivity.

To maximize the benefits of modern industrial machinery, consider implementing the following tips. First, assess your specific operational needs and identify gaps where technology can provide solutions. Tailoring machinery to meet your unique requirements ensures that you harness the full potential of technological advancements. Second, prioritize machinery that supports easy upgrades and integration with new technologies, as fast-evolving innovations can significantly enhance operational capabilities over time. Finally, invest in training your workforce on new technologies; a well-informed team can properly utilize the equipment, ensuring the machinery operates at optimal efficiency.

By prioritizing technology in your machinery selection process, you set the foundation for a more productive and efficient industrial operation. Embracing innovations not only positions your business competitively in the market but also fosters a culture of continuous improvement.

Productivity Gains from Industrial Machinery Adoption

Evaluating Machinery Based on Production Capacity and Scaling Needs

When it comes to selecting industrial machinery, evaluating production capacity in relation to your scaling needs is imperative for maximizing efficiency and productivity. According to a report by the McKinsey Global Institute, companies that adopt advanced machinery and automate their production processes can improve productivity by up to 20-25%. This potential growth underscores the importance of choosing equipment that not only meets current demands but also accommodates future expansion.

In examining production capacity, consider the machinery's throughput rates and how they align with your business's operational goals. A study by the National Association of Manufacturers highlights that manufacturers with scalable equipment are 30% more likely to achieve their production targets. It is essential to analyze the specifications of machinery to ensure it can handle an increase in output without compromising quality. A careful assessment of these factors allows businesses to avoid over-investment in underutilized tools while still being prepared for growth opportunities as market demands fluctuate.

Maintenance and Support Services: Key Components for Productivity

When selecting industrial machinery, the focus should not solely be on the equipment's capabilities but also on the maintenance and support services that come with it. These services play a vital role in ensuring long-term productivity and efficiency. Regular maintenance schedules prevent unexpected breakdowns that can halt operations and lead to costly downtime. By having a reliable maintenance plan in place, businesses can significantly enhance the lifespan of their machinery and optimize their performance.

Furthermore, the availability of robust support services is crucial when issues arise. Experience and expertise in troubleshooting can minimize response times and quickly restore operations to normal. Organizations should seek manufacturers or suppliers who offer comprehensive support, including training for operators, availability of spare parts, and accessible technical assistance. Such features not only assure productivity but also instill confidence in the operational capabilities of the machinery.

Ultimately, investing time in understanding the maintenance and support services associated with industrial machinery ensures a smoother operational flow. It allows companies to focus on their core activities while maintaining high levels of efficiency and productivity through well-supported equipment. Such strategic planning is essential for fostering long-term growth and a competitive edge in the industry.

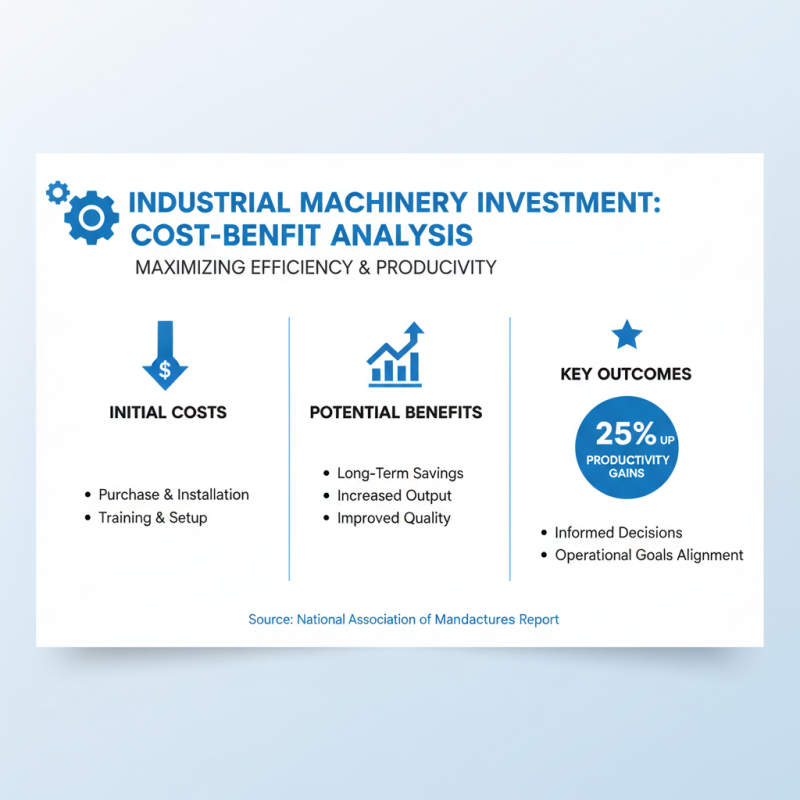

Cost-Benefit Analysis: Budgeting for Industrial Machinery Investments

When planning for industrial machinery investments, conducting a thorough cost-benefit analysis is critical in maximizing both efficiency and productivity. A recent report by the National Association of Manufacturers indicates that effective budgeting for such investments can lead to productivity gains of up to 25%. By analyzing not only the initial costs associated with purchasing and installing new machinery but also the potential long-term savings and increased output, businesses can make more informed decisions that align with their operational goals.

One essential aspect to consider in the cost-benefit analysis is the machine's operational efficiency. The U.S. Department of Energy's Industrial Technologies Program suggests that companies can reduce energy costs associated with manufacturing processes by as much as 30% through the adoption of advanced technologies. Evaluating machinery not just on purchase price but also on operating costs, maintenance requirements, and lifespan can significantly impact the overall return on investment (ROI). For companies that neglect these factors, the hidden costs of inefficiency can quickly erode potential gains, highlighting the importance of a comprehensive analysis before committing to machinery investments.

Related Posts

-

Top 10 Plant Machinery Types You Need to Know for Your Business

-

Top 10 Essential Tips for Choosing Euro Machinery in Your Industry

-

How to Choose the Right Metal Working Machines for Your Projects

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

2025 Guide: How to Choose the Best Extruder Machine for Your Needs

-

Top CNC Machine Auctions: How to Find the Best Deals and Tips for Bidders