Top 10 Plant Machinery Types You Need to Know for Your Business

In the ever-evolving landscape of the construction and manufacturing industries, understanding the various types of plant machinery is paramount for any business aiming to thrive. Jason Thompson, a leading expert in plant machinery with over two decades of experience, once stated, "Investing in the right plant machinery is not just an operational decision; it's a strategic move that can significantly impact your business's efficiency and profitability." This underscores the importance of familiarizing oneself with the essential types of equipment that can streamline operations and enhance productivity.

As businesses strive to stay competitive, the demand for efficient and reliable plant machinery continues to grow. The right machinery varies depending on the nature of projects, the scale of operations, and specific industry requirements. From excavators and loaders to cranes and concrete mixers, each type of plant machinery plays a critical role in ensuring that tasks are completed on time and to the highest standards. In this article, we will explore the top 10 types of plant machinery that you need to know, arming you with the knowledge to make informed decisions that will shape the future of your business.

Types of Plant Machinery Essential for Various Industries

When it comes to running a successful business in industries such as construction, agriculture, and manufacturing, understanding the various types of plant machinery is crucial. Different sectors require specific machinery to improve efficiency, safety, and productivity. For instance, in construction, excavators and bulldozers play a vital role in earthmoving and site preparation, while cranes are essential for lifting heavy materials to great heights. These machines not only expedite tasks but also enhance the overall quality of work.

In agriculture, tractors and harvesters are indispensable for modern farming operations. Tractors facilitate a wide range of tasks from plowing to planting, while harvesters are designed to efficiently gather crops, significantly reducing the labor force needed. Meanwhile, in the manufacturing sector, equipment like conveyor belts and industrial robots are extensively used to streamline production processes, ensuring consistency and reducing human error. As industries evolve, the adoption of these essential plant machinery types not only drives operational effectiveness but also paves the way for technological advancements within each field.

Top 10 Plant Machinery Types You Need to Know for Your Business

| Machinery Type | Industry | Primary Function | Key Features |

|---|---|---|---|

| Excavator | Construction | Digging and earth removal | Versatile arm, various attachments |

| Bulldozer | Construction | Moving large quantities of earth | Powerful blade, rugged tracks |

| Forklift | Warehouse/Logistics | Lifting and transporting materials | Maneuverability, adjustable forks |

| Backhoe Loader | Construction | Excavation and loading materials | Dual functions (front and rear) |

| Crane | Construction | Lifting heavy materials | Reach height, load capacity |

| Paver | Road Construction | Laying asphalt and concrete | Precision and even layering |

| Skid-Steer Loader | Construction/Agriculture | Compact material handling | Versatile attachments, tight spaces |

| Telehandler | Construction/Agriculture | Lift and place heavy loads | Extendable arm, maneuverability |

| Compactor | Construction | Soil and asphalt compaction | Vibratory and static compaction options |

| Chipper/Shredder | Landscaping/Agriculture | Reducing tree branches and vegetation | Powerful motor, various chip sizes |

Overview of Construction Machinery: Types and Functions

Construction machinery plays a vital role in the efficiency and effectiveness of various projects, ranging from road construction to large-scale building developments. Understanding the different types and their functions helps businesses select the right equipment for their specific needs. Common types include excavators, which are essential for digging and earth-moving; bulldozers, used for pushing large quantities of materials; and cranes, which facilitate the lifting and movement of heavy objects. Each piece of machinery contributes to the overall workflow, enhancing productivity while ensuring safety on the job site.

Tips: When selecting construction machinery, always consider the scale of your projects and the specific tasks you aim to accomplish. Training your staff on proper machine operation is crucial for maintaining safety standards and maximizing efficiency. Additionally, investing in maintenance plans can prolong the lifespan of equipment and reduce costs in the long run.

Another significant category includes compact machinery such as skid-steer loaders and mini-excavators, which are ideal for small and confined job sites where space is limited. Their versatility allows them to perform a variety of tasks, from grading to landscaping. Understanding these machines’ unique functionalities will enable businesses to streamline operations and ensure that projects are completed on time and within budget.

Tips: Always conduct thorough research before purchasing or renting equipment. Evaluate factors such as fuel efficiency, ease of operation, and potential resale value. Collaborating with experienced operators can also lead to better decision-making when it comes to machinery use on-site.

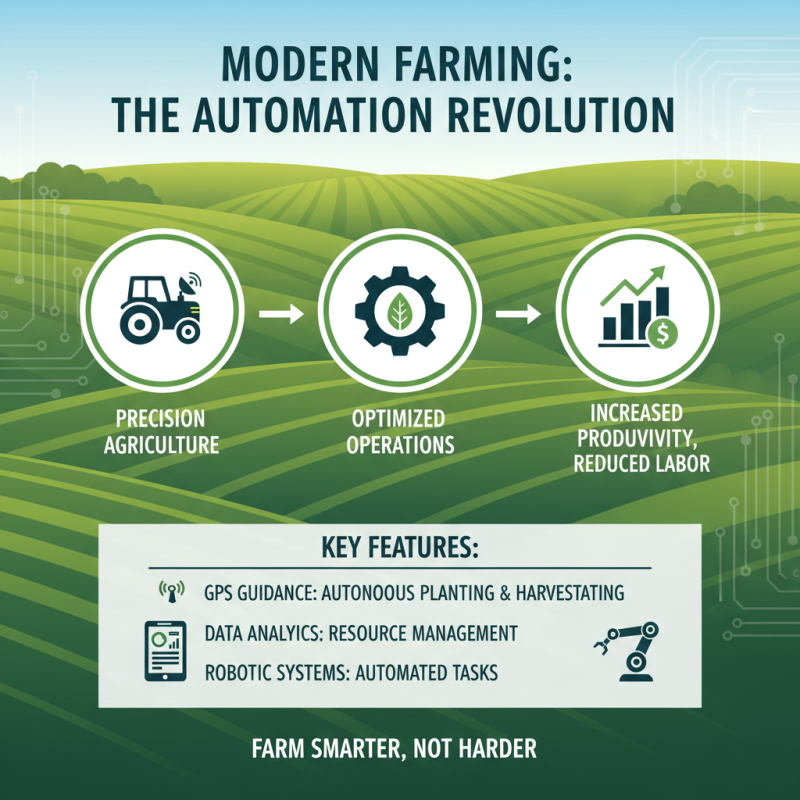

Key Features of Agricultural Machinery for Modern Farming

Modern farming relies heavily on advanced agricultural machinery to enhance efficiency and productivity. One of the key features of contemporary agricultural machinery is automation. With the integration of automated systems, farmers can streamline operations, minimize labor costs, and achieve more consistent results. Machines equipped with GPS technology allow for precise planting, fertilization, and harvesting, enabling farmers to make the best use of their land and resources.

Another important aspect of modern agricultural machinery is versatility. Many machines are designed to perform multiple functions, such as tilling, planting, and even irrigation. This adaptability can significantly reduce the need for several pieces of equipment, saving space and maintenance costs. Additionally, innovations such as precision agriculture tools enhance decision-making through data analysis, helping farmers optimize crop yields while conserving water and fertilizers, thus promoting sustainable practices in farming.

Understanding Earthmoving Equipment: Types and Applications

Understanding earthmoving equipment is crucial for any business involved in construction, landscaping, or excavation. There are several key types of machinery in this category, each designed to serve specific functions.

Excavators are among the most versatile machines, equipped with a boom, stick, and bucket to dig and move large amounts of earth. They are ideal for trenching, demolition, and site preparation.

Similarly, bulldozers are powerful vehicles equipped with wide blades, perfect for pushing earth and rubble, making them essential for clearing sites and grading land.

Another important type of earthmoving equipment is the backhoe loader, which combines the functionalities of a tractor, a front loader, and an excavator. This machine is particularly useful for smaller jobs where space is limited, offering both digging and loading capabilities.

Meanwhile, wheel loaders provide efficient loading solutions for transporting materials around a site, and compactors help ensure that the ground is compressed and stable for construction activities.

Understanding the applications and benefits of these various types of earthmoving machinery can significantly enhance operational efficiency and productivity in any construction-related business.

Importance of Material Handling Equipment in Manufacturing Operations

In the realm of manufacturing operations, material handling equipment plays a pivotal role in enhancing productivity and ensuring efficient workflows. According to a report by the Material Handling Industry of America, companies that invest in advanced material handling systems can see productivity improvements of up to 30%. This is critical as modern manufacturing demands agility and precision, where every second counts. Utilizing cuttinedge equipment allows businesses to minimize downtime, streamline operations, and ultimately reduce operational costs.

When selecting material handling equipment, it's essential to consider specific factors that align with your business needs. For example, understanding the weight and dimensions of the products being handled can inform your choice of machinery, ensuring that it can accommodate your requirements without compromising safety. Tip: Regularly schedule maintenance checks on your equipment to prevent breakdowns and maintain optimal efficiency.

Moreover, integrating automation into your material handling processes can further enhance operational effectiveness. Data from the International Federation of Robotics suggests that companies implementing automated systems can improve their processing speed by 25% or more. This shift not only supports a faster turnaround but also increases workplace safety by reducing manual labor. Tip: Invest in training your workforce to adapt to these technologies, ensuring that human expertise can complement automated operations for the best results.

Related Posts

-

What is the Importance of Construction Machines in Modern Construction Projects?

-

How to Choose the Right Heavy Machinery for Your Construction Projects in 2025

-

Why Choose an Equipment Trader: Benefits for Buyers and Sellers in Construction

-

2025 How to Choose the Right Heavy Equipment Machinery for Your Project

-

What is Machinery Parts and Their Importance in Modern Manufacturing

-

Top 5 Second Hand Industrial Equipment Options for Your Business Needs